Polycarbonate vs. nylon: Which one is better for plastic manufacturing?

People often pay attention to the comparison of polycarbonate vs. nylon as they are both durable and affordable choices in manufacturing plastic products. There are key features setting these two materials apart with their set of advantages and disadvantages.

So, nylon vs. polycarbonate, which one should you choose for your project? Let's find out in our article right now!

1. What is Polycarbonate?

Polycarbonate plastic, or PC plastic, is a common amorphous thermoplastic. Despite the factory-made color, it's naturally transparent, allowing light to go through. That's why it's often used as a glass alternative in many transparency-required products such as protective shields, bullet-prove glass, lenses for eyeglasses, digital disks, exterior lighting fixtures, greenhouses, and protective gear. In addition, polycarbonate is impact and heat resistant, and flame retardant, making it a suitable engineering plastic for competent and durable products.

Polycarbonate

2. What is Nylon?

Nylon, consisting of polyamides, refers to a family of synthetic polymers. This silk-like thermoplastic is often made from petroleum. After the melting process, it can turn into different shapes, films, or fibers. Manufacturers usually add some additives to the material to obtain various outstanding properties. Nylon is widely used in many applications in shapes (car's electrical equipment or molded parts), in films (food packaging), and in fibers and fabric (clothing or flooring and rubber reinforcement). Besides, the material can tolerate heat, wear, and chemicals.

Read more: What is nylon? All about its properties and common uses

Nylon

3. Polycarbonate Vs. Nylon - Comparison

3.1. Property Values

| |

Polycarbonate |

Nylon |

| Flexural Modulus |

410,000 |

410,000 - 500,000 |

| Tensile Strength |

12,400 |

10,000 - 13,500 |

| Water Absorption Rating |

1.2 |

0.6 - 1.2 |

| Coefficient of Linear Thermal Expansion |

4.5 |

4.5 - 5 |

3.2. Outstanding Features

| Polycarbonate |

Nylon |

- Easy to machine

- Glass-filled grades, enhanced bearing and wear grades, and FDA-compliant grades are available

- Good impact resistant

|

- Machinable

- Low coefficient of friction

- Glass-filled grades, enhanced bearing and wear grades, and FDA-compliant grades are available

|

3.3. Applications

| Polycarbonate |

Nylon |

|

|

- Electrical household appliances

- Electrical components (housings and covers for power distribution, battery boxes, connectors, etc.)

- Gaskets and seals

- Rollers and wheels

- Machinery components for food processing

|

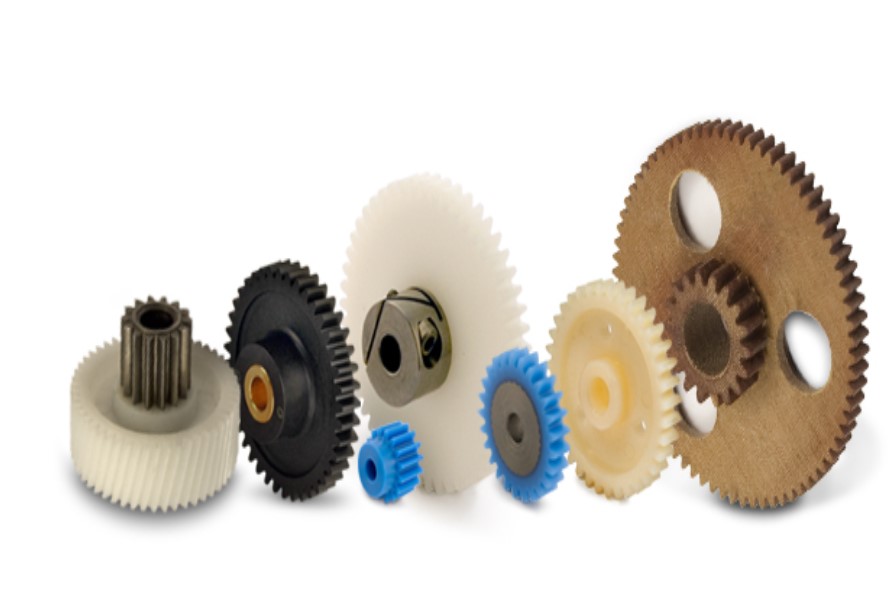

- Gears

- Rollers and wheels

- Wear pads & components

- Gaskets and seals

- Machinery components for food processing

|

4. Polycarbonate Vs. Nylon - Which Should Be Chosen for Plastic Manufacturing?

Polycarbonate is stronger and more durable than nylon. In addition, this thermoplastic polymer also has good resistance to chemical, weathering, and UV radiation exposure. However, since its melting point is high, sometimes, it may be struggling to work with. For example, when you want to form it into a desired shape, you may need special equipment or machinery to get the job done. Besides, polycarbonate is usually more expensive than nylon.

Nylon is a lightweight yet strong material. Its final products often last quite long thanks to its high wear and tear resistance. The manufacturing process does not require a lot except for the extrusion or injection molding processes. Nylon has a cheaper price tag than other materials, such as aluminum and steel. However, when compared to polycarbonate, its rigidity, and durability can be doubtful in certain applications.

As such, while choosing between the two choices, nylon vs. polycarbonate, you should see what criteria your products require and what the prioritized requirements are and consider each material's pros and cons to see which one is suitable.

Nylon is more affordable, making it an ideal choice to gain cost-effectiveness without compromising performance. Meanwhile, when your target is quality over cost savings, consider polycarbonate.

5. About EuroPlas Polycarbonate Engineering Plastic Compound

Polycarbonate engineering plastic compound is mixed between the polycarbonate base, reinforcing agents, and additives. Its purpose is to create a material meeting the property requirements of the final products.

As a leader in the masterbatch manufacturing field, Europlas understands the need for a full-function-in-one material to save time and cost of production. The end products can achieve special properties thanks to the compound. Engineering plastic is commonly seen in electronics and automobile manufacturing, interior design, and renewable energy.

In general, the most common reinforcements include glass fibers and beads, talc, barium sulfate, and conductive carbon. As for the polycarbonate engineering plastic compound of Europlas, the most highlighted products are the PC glass fiber compound and PC flame retardant compound.

Their outstanding features include the following:

- All functions in one single material

- Directly processed capability (no adding materials required)

- Tailor-made based on the final products' criteria

- Provide the end products with better stiffness, impact strength, and thermal ability.

5.1. PC Glass Fiber Compound

PC glass fiber compound

As its name states, EuroPlas PC glass fiber compound is a mixture of polycarbonate resin and glass fiber. PC-GF compound has excellent properties of a thermoplastic polymer, such as rigidity, heat, and impact resistance.

Besides, thanks to the combination, the compound's mechanical properties are improved. It has better dimensional stability, tensile and flexural strength, and impact resistance. That's why it's suitable for final products requiring high stiffness and durability. Its applications include gears, keyboards, vacuum cleaners, rice cookers, cameras, and printers.

EuroPlas's high-quality PC-GF compounds can be made with various glass fiber ratios to obtain specific mechanical properties that meet the customers' requirements.

5.2. PC flame retardant compound

PC flame retardant compound

EuroPlas's PC flame retardant compound perfectly combines polycarbonate resin and halogen flame retardant. It's lightweight, transparent, durable, impact-resistant, and high-temperature resistant, making it suitable for optical applications and electrical insulators.

EuroPlas's mixture of polycarbonate plastic and flame retardant is available with different ratios to meet the requirement of varying UL94 standard fireproof levels such as 5VA, 5VB, V0, V1, and V2. It's a perfect candidate for applications requiring enhanced safety features, such as electronic components, mobile chargers, power sockets, earphones, and keyboards.

Our high-quality mechanical and thermal products ensure safety without compromising performance. Therefore, Europlas is a reliable supplier for manufacturing companies looking for a safe and high-quality PC flame retardant compound, as well as other polycarbonate engineering plastic compounds.

The Bottom Lines

The discussion about polycarbonate vs. nylon has come to an end. In brief, each has its own pros and cons and can be chosen for plastic manufacturing. If you want a tough, durable, and reasonably-priced material, go for the polycarbonate. Get a free consultation with EuroPlas, and we'll help you to choose the best engineering plastic compound for your projects.