In a world where materials play a pivotal role in the development of innovative solutions, polystyrene sheets have carved a niche for themselves. Known for their lightweight and durable nature, these versatile plastic sheets are used in a myriad of applications ranging from arts and crafts to industrial manufacturing. But what makes them so unique, and why are they a go-to choice for professionals and hobbyists alike?

This article dives deep into the world of polystyrene sheets, offering an overview of their characteristics, applications, and benefits while also highlighting safety tips to ensure responsible handling. Lastly, we introduce EuroPlas, the global leader in filler masterbatch production and a pioneer in innovative material solutions, to showcase their impact on this industry.

1. Overview of Polystyrene Sheets

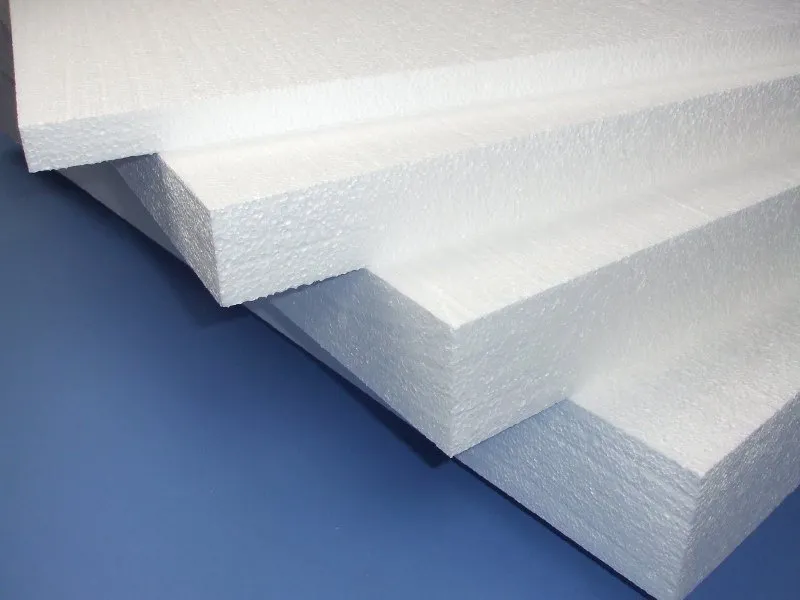

Polystyrene sheets are a type of thermoplastic material derived from styrene, a liquid hydrocarbon that undergoes polymerization to create solid, durable sheets. Polystyrene, being one of the most widely used plastics globally, is characterized by its rigidity, thermal insulation properties, and resistance to moisture and chemicals.

Polystyrene sheets are derived from styrene

Types of Polystyrene Sheets

Expanded Polystyrene (EPS): Known for its lightweight and insulating properties, EPS is commonly used in packaging, construction, and crafts.

Extruded Polystyrene (XPS): This type is denser and offers superior strength, making it suitable for high-stress applications such as insulation boards and architectural models.

General Purpose Polystyrene (GPPS): Transparent and versatile, GPPS is often used in displays, lighting diffusers, and decorative projects.

Physical Properties:

Lightweight yet rigid, making it easy to handle and process.

Resistant to water, chemicals, and temperature changes.

Excellent thermal and acoustic insulation.

These characteristics make polystyrene sheets a versatile material that is widely used across industries for both functional and decorative purposes.

2. Applications of Polystyrene Sheets in Arts and Crafts

Polystyrene sheets have emerged as a favored material in the creative world due to their versatility and adaptability. Whether for professional projects or personal hobbies, their unique characteristics allow artists and crafters to push the boundaries of their imagination.

Model-Making

Polystyrene sheets are indispensable in creating detailed architectural, engineering, and miniature models. Their ability to be easily cut, shaped, and painted ensures high levels of precision, a critical factor in model-making. For instance:

Architectural Models: Architects rely on polystyrene sheets to bring design concepts to life. The material's lightweight nature allows for the construction of large-scale models that are easy to transport and modify.

Engineering Prototypes: Engineers use polystyrene sheets to craft prototypes, enabling them to test structural designs and refine details before full-scale production.

Miniatures for Gaming or Dioramas: The durability and customization options of polystyrene sheets make them perfect for creating intricate miniatures used in tabletop gaming or diorama displays.

Custom Decorations and Home Décor

Applications of polystyrene sheets

Craft enthusiasts and interior designers use polystyrene sheets to fabricate unique decorative pieces that bring spaces to life. These include:

Wall Art and Murals: Polystyrene sheets can be engraved or painted to create stunning wall art. Their smooth surface and lightweight properties make them easy to mount or hang.

Thematic Event Décor: For events like weddings, birthdays, and exhibitions, polystyrene sheets are ideal for crafting thematic decorations such as oversized letters, logos, or ornamental structures.

Seasonal Decorations: From Halloween tombstones to Christmas snowflakes, polystyrene sheets are perfect for making seasonal decorations due to their ease of cutting and painting.

Educational and School Projects

Teachers and students often turn to polystyrene sheets for hands-on learning and creative projects. Examples include:

Science Fair Models: Students use polystyrene to build models of the solar system, animal habitats, and volcanic eruptions, taking advantage of the material's malleability and affordability.

Mathematical Shapes and Geometry: For lessons in geometry, polystyrene sheets are used to create 3D shapes that demonstrate concepts like volume and surface area.

Event and Stage Design

Polystyrene sheets are widely used in creating lightweight props, backdrops, and set pieces for theatrical productions, film sets, and events. Designers favor them for their ability to mimic various textures and finishes, such as wood, metal, or stone, at a fraction of the cost and weight.

DIY Crafting Tools and Accessories

Applications of polystyrene sheets in crafting

For DIY enthusiasts, polystyrene sheets are more than just raw material—they also serve as tools and accessories for crafting. Examples include:

Stencils and Templates: Polystyrene sheets can be carved into reusable stencils for painting, etching, or embossing.

Storage and Display Solutions: Craft enthusiasts often repurpose polystyrene sheets to create storage boxes, jewelry displays, or organizer trays.

The limitless potential of polystyrene sheets in arts and crafts stems from their unique properties, which allow users to create functional and visually appealing projects with minimal effort.

3. Benefits of Using Polystyrene Sheets

Polystyrene sheets are not just popular; they’re practical, versatile, and eco-conscious, making them an exceptional choice across industries. Below, we explore their numerous benefits in greater detail.

Affordability

One of the most significant advantages of polystyrene sheets is their cost-effectiveness. Compared to materials like wood, metal, or acrylic, polystyrene sheets offer a more affordable solution without compromising on quality. This makes them accessible to individuals and businesses alike.

Budget-Friendly for Bulk Use: Ideal for projects requiring large quantities, such as packaging or construction.

Accessible for Hobbyists: Affordable pricing ensures that even casual DIY enthusiasts can enjoy their benefits.

Lightweight and Easy to Handle

Polystyrene sheets are easy to handle

Polystyrene sheets are remarkably lightweight, making them easy to transport, cut, and assemble. This property is particularly advantageous for large-scale projects or applications requiring frequent handling.

Transportation Benefits: Reduced weight cuts down shipping costs and simplifies installation processes.

User-Friendly Crafting: Even beginners can work with polystyrene sheets without needing heavy-duty tools.

Customizability

Polystyrene sheets offer unmatched flexibility for customization, making them suitable for a wide array of uses.

Easily Shaped: They can be cut, sanded, or molded into intricate shapes using basic tools like knives, scissors, or hot wire cutters.

Paint and Finish Ready: Polystyrene sheets take paint well, allowing users to create vibrant, professional-looking finishes.

Variety of Thicknesses: Available in multiple thicknesses, they cater to specific project requirements, from delicate craftwork to robust industrial uses.

Durability and Longevity

Polystyrene sheets are resistant to moisture, chemicals, and temperature fluctuations, ensuring long-lasting performance in various environments.

Weather Resistance: Ideal for outdoor use in signs or decorative elements.

Chemical Resistance: Commonly used in laboratory settings or industrial applications requiring exposure to chemicals.

Thermal and Acoustic Insulation

Applications of polystyrene sheets

Thanks to their excellent thermal insulation properties, polystyrene sheets are widely used in temperature-sensitive applications.

Building Insulation: Used in walls, roofs, and flooring to maintain indoor temperatures and reduce energy costs.

Soundproofing: Effective in dampening noise, polystyrene sheets are used in recording studios, theaters, and home offices.

Eco-Friendly Options

The push for sustainability has led to innovations in polystyrene production, making it an eco-friendlier material.

Recyclability: Many types of polystyrene sheets are recyclable, reducing their environmental footprint.

Biodegradable Alternatives: Manufacturers like EuroPlas are introducing biodegradable polystyrene sheets, offering a greener option for conscientious consumers.

Safety and Hygiene

Polystyrene sheets are non-toxic and safe for food-related applications, such as packaging or insulation for food delivery containers. They also resist bacterial growth, making them suitable for use in hygienic environments like hospitals and laboratories.

Time-Efficiency

Due to their lightweight and customizable properties, polystyrene sheets help save time during production and assembly.

Fast Installation: Simple tools and methods enable quick setup for projects like signage or insulation.

Reduced Labor Costs: Fewer resources and personnel are required to work with polystyrene compared to heavier or more complex materials.

Versatility Across Industries

From crafting to construction, the adaptability of polystyrene sheets allows them to cater to a wide range of applications:

Packaging: Widely used for protective packaging due to its shock-absorbing properties.

Signage: A go-to material for custom signs and displays due to its lightweight and smooth surface.

Construction: Used in lightweight concrete panels, thermal insulation boards, and decorative elements.

Polystyrene sheets have redefined the possibilities of modern materials, proving their worth in both creative and functional applications. Their diverse benefits make them indispensable for anyone seeking a reliable, cost-effective, and adaptable solution.

4. Safety Tips for Working with Polystyrene

Applications of polystyrene sheets

While polystyrene sheets are user-friendly and safe for most applications, following proper safety measures is crucial to avoid potential hazards.

Work in a Ventilated Space

Cutting or sanding polystyrene sheets can produce fine dust particles. Always work in a well-ventilated area or use a dust extraction system to minimize inhalation risks.

Wear Protective Gear

Use gloves to protect your hands from sharp tools and safety goggles to shield your eyes from flying debris. A dust mask is recommended when cutting or sanding polystyrene.

Handle Heat with Caution

Polystyrene melts at high temperatures and can release toxic fumes when burned. Avoid using open flames or high-heat tools near polystyrene sheets. If heat is required for shaping, use controlled methods like a hot wire cutter.

Store Properly

Keep polystyrene sheets away from direct sunlight, excessive heat, or flammable materials to prevent deformation or accidental ignition.

Dispose Responsibly

Although polystyrene is recyclable, not all recycling facilities accept it. Research local recycling guidelines or consider reusing scrap material in other projects to minimize waste.

By adhering to these safety tips, users can maximize the benefits of polystyrene sheets while minimizing risks.

5. Conclusion

Polystyrene sheets are a versatile, cost-effective, and durable material that has earned its place in industries ranging from arts and crafts to construction and packaging. Their unique properties, including lightweight composition, ease of customization, and thermal insulation, make them invaluable for creative and practical applications alike.

As the demand for sustainable and innovative materials grows, companies like EuroPlas are leading the way in providing high-quality, eco-conscious solutions for polystyrene sheets and other plastic materials. Whether you’re a professional designer, a DIY enthusiast, or an industrial manufacturer, polystyrene sheets offer endless possibilities for your projects.

6. About EuroPlas

EuroPlas - No. 1 3D printing material manufacturer

EuroPlas (EuP) is the world’s leading filler masterbatch manufacturer, committed to providing innovative and high-quality plastic solutions to elevate the competitiveness of businesses worldwide. With a strong focus on ABS compounds and other essential 3D printing materials, EuroPlas is a trusted partner for industries looking to improve efficiency and sustainability.

EuP operates seven factories across Vietnam, spanning dozens of hectares, and produces up to 0.8 million tons annually. This extensive manufacturing capacity enables EuP to fulfill large-scale orders for clients in over 95 countries. With state-of-the-art equipment, such as extruders and injection molding machines, EuP guarantees products that meet the highest standards of quality and consistency.

What’s the wait? Visit our Contact Us page to learn how EuroPlas can help your business thrive.