Filler masterbatch containing sodium sulfate (transparent Na2SO4 filler masterbatch) is a high-end quality product belonging to the transparent fillers category beside Talc and Barium Sulfate masterbatch. This article aims to give our customers a broad view of this product.

1. Overview of filler masterbatch containing sodium sulfate

The most important component of this filler masterbatch is obviously sodium sulfate, which chemical formula is Na2SO4. This is an inorganic compound that is also called the sulfate of soda. In nature, sodium sulfate is found in many forms, ranging from anhydrous (known as thenardite mineral) to decahydrate (known as mirabilite mineral or Glauber’s salt). The vast majority of worldwide sodium sulfate production is in the form of decahydrate with approximately 5.5 to 6 million tonnes annually (Mt/a).

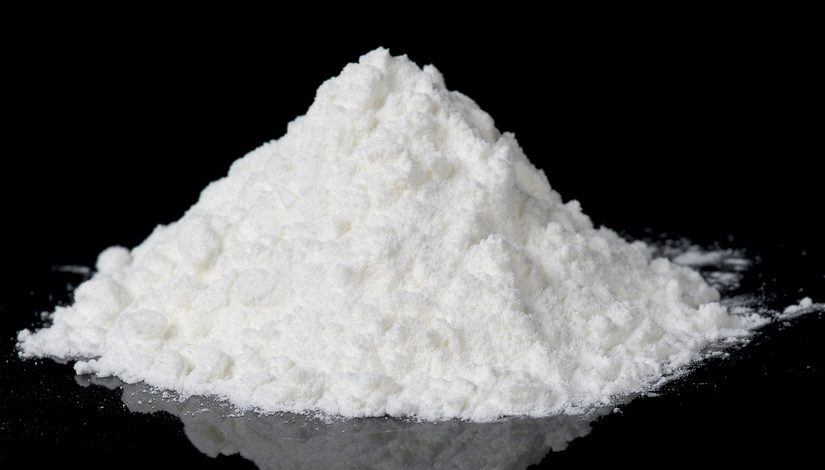

All forms of this compound appear in tasteless and odorless white crystalline solid powder. Na2SO4 is highly soluble in water and this solubility fluctuates with different temperatures following the trend in which its solubility tends to increase when the temperatures rise. It is also soluble in glycerol and hydrogen iodide but insoluble in ethanol.

2. Na2SO4 filler masterbatch is produced with high-tech nano technology

EuP’s sodium sulfate masterbatch is mainly used for superior PP, and PE packing materials. This type of transparent filler masterbatch is produced by high-tech nanotechnologies. It comprises nano functional materials (anhydrous Na2SO4 powder) compounded with suitable plastic carriers and several additives as its raw materials. Nano Grade Powder size is up to 8000 mesh, which ensures it with superior surface modification functions. The filling effect attained from Nano Grade Powder in sodium sulfate master batch shows excellent glossiness, very good transparency, and strong tensile strength in the final products.

3. EuP’s filler masterbatch containing Na2SO4 and its features

Sodium sulfate transparent filler masterbatch of EuP expresses high transparency and excellent glossiness. It also has strong mechanical properties with very good dispersion, high tenacity, and strong stability features. Another advantage of this masterbatch is that all components are non-toxic factors and friendly to the environment while the required costs during production are relatively low. Na2SO4 transparent filler masterbatch can be widely used as a superior performance environmentally friendly material to take place of a certain portion of plastic raw material for LLDPE, LDPE, HDPE, and PP plastic products and won't change the performance of the basic materials at the same time but largely reduce the whole processing costs. Additionally, Na2SO4 masterbatch resists acids, alkaline, and high temperature.

4. Na2SO4 filler masterbatch can be applied in what fields?

Sodium sulfate masterbatch can be used in various productions since it is compatible with PP (polypropylene) and PE (polyethylene) – the two most commonly used plastics in the world. Na2SO4 filler masterbatch containing about 70% sodium sulfate powder can be widely used in:

- Producing agricultural film and mulch film with LLDPE plastic as a carrier

- Producing rolling bags, shopping bags, high-quality transparent blowing products with HDPE and LDPE resin as carriers

- Producing specular injection molded parts with HDPE and PP resin carriers

This transparent filler can be used to take place as a part of raw material, largely saves material costs, and has some effects on improving transparency and plastic performance in general. Besides the previous applications, Na2SO4 masterbatch is also found in noble tableware, disposable tableware (dishes, glasses, forks, knives, cups, lunch-box, etc.), pipes, sheets, and laminated products manufactured by injection molding, extrusion molding, and blown film molding.

5. Sodium sulfate filler masterbatch and the perfect dosage rates in plastic products manufacturing

For each specific application, sodium sulfate filler masterbatch is recommended to be used at different dosage rates. If you are aiming to use Na2SO4 masterbatch with LLDPE resin as a carrier to produce agriculture film or mulching film, the recommended dosage is 5 – 30%. For other applications, such as manufacturing rolling bags, shopping bags, or high-end transparency blown film products made of HDPE or LDPE the recommended dosage is much higher, accounting for 30 – 50% of total input materials.

To be specific, in order to produce high-standard quality HDPE films and LLDPE films, the additional amount of sodium sulfate filler masterbatch must be up to 50% and more than 30%, respectively. With these large adding rates, the films are still able to maintain their own original mechanical and physical properties while their optical feature is increased at the same time. Therefore it is popular for being used as a filler in high-quality packaging material production.

To be specific, in order to produce high-standard quality HDPE films and LLDPE films, the additional amount of sodium sulfate filler masterbatch must be up to 50% and more than 30%, respectively. With these large adding rates, the films are still able to maintain their own original mechanical and physical properties while their optical feature is increased at the same time. Therefore it is popular for being used as a filler in high-quality packaging material production.

6. EuroPlas - The world's largest filler masterbatch manufacturer

European Plastic Company (EuroPlas) is the world's largest filler masterbatch manufacturer headquartered in Vietnam. EuroPlas filler masterbatch products are quality-tested products that have satisfied thousands of customers in more than 85 countries around the world. This product is a cost-effective solution and helps you enhance many of the properties of the final product such as brightness, opacity and reduced shrinkage.

If you would like to know more details about our filler masterbatch product in particular, as well as our other masterbatches, please fill out this form or contact us via email/phone number. We are happy to answer all your product questions and concerns!