Processing aids have the function as their name suggests, the raw material plays an important role in the production process of plastic products. They not only reduce the rate of defective production, maintain the efficiency of the long-term processing process but also ensure the quality of the final product. In particular, processing aids are the perfect choice to overcome common problems such as: fish skin phenomenon, rough surface, striped surface, fish eye phenomenon or black spots. Those are just the basic functions of processing aids, refer to the article below to know the 8 main functions of PPA.

Read more: What are plastic additives? 8 most common plastic additives in plastic industry

1. Overview of processing aids

Polymer processing aids (PPA) are a combination of plastic additive groups with a fluoropolymer base manufactured with the core goal of supporting & improving the processing of popular polymer groups such as Polyolefins and other Polymers. The recommended usage level is in the range of 200/million -1000/million (200ppm -1000ppm)

Basically, the mechanism of action of polymer processing aids (PPA) is to affect the physical structure & chemical properties of raw materials to minimize unwanted incidents. In particular, PPA can affect & control thermal conditions during long-term processing to ensure the highest quality output rate.

Therefore, the core purpose of polymer processing aids (PPA) is product quality and production costs, which helps manufacturers maintain stable development and save a lot of costs throughout the raw material processing process. This is an overview of polymer processing aids (PPA). In the following section, EuroPlas will provide customers with the main functions of processing aids.

.jpg)

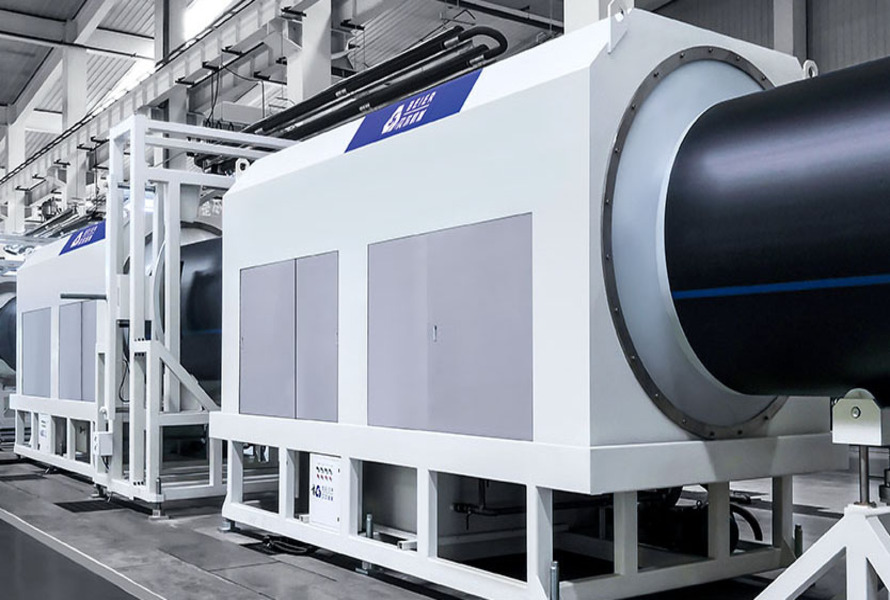

Processing aids play an extremely important role in the production of plastic products with structures ranging from basic to complex.

2. What are the functions of processing aids?

PE and PVC applications are often combined with processing aids (PPA). In addition, some PP types with narrow molecular weight distribution and some styrene, polyamide, acrylic and thermoplastic elastomer polymers also benefit from processing aids. Polymer processing aids (PPA) are fully utilized thanks to the following main functions:

2.1. Minimize melting and fracture

The phenomenon of sticking and melting occurs when the Polymers stick to the mold wall. This is the time when the pressure and stress at the mold wall of the plastic machine are increased rapidly to separate the polymer from the metal surface. Therefore, if this process takes place for a long time, it will not only affect the surface quality, product quality but also equipment depreciation.

The great solution is to coat the mold wall with a suitable processing aid. EMPA 05D is a plastic processing aid with low surface energy. It sticks to the metal and does not stick to the extruded plastic. Gradually, a processing aid coating is formed on the metal surface when the polymer passes through the mold.

2.2. Surface coating for the mold wall

The basic working mechanism of the processing aid is to form a fluorine coating that adheres to the mold and the cylinder of the extruder. This is considered an extremely effective lubricant between the plastic and the metal wall of the machine. The core effect is to minimize friction and form a smoother plastic flow. In this case, the processing aid will bring the benefit of saving energy consumption for the manufacturer as well as increasing efficiency because the pressure has been significantly eliminated.

Processing aids ensure durability and smooth operation of components in plastic manufacturing systems.

2.3. Increase the features of the final product

As EuroPlas mentioned above, plastic processing additives not only have a positive impact on the production equipment but also on the plastic raw materials during the processing process. Because of the stable flow, plastic particles will easily dissolve with other plastic additives, thereby clearly forming outstanding features for the final product. Next, the special chemical structure of PPA containing fluoropolymer does not occur incompatible with other additive components. Therefore, PPA supports a smoother mixing process, distributes heat reasonably and contributes to preventing the shiny appearance of the extrusion head (Die Build-up), shark skin (Shark skin).

-c%E1%BA%A3i-thi%E1%BB%87n-%C4%91%E1%BB%99-s%C3%A1ng-v%C3%A0-b%C3%B3ng-c%E1%BB%A7a-th%C3%A0nh-ph%E1%BA%A9m-cu%E1%BB%91i.jpg)

Processing aids (PPAs) improve the brightness and gloss of the final product.

2.4. Increase the ability to fill the mold

The flow of plastic during the processing plays a very important role and determines the quality of the final product. In particular, processing aids (PPA) help eliminate the lumpiness or crystallization of the plastic mixture, so they can increase the ability to fill the mold for technical plastic injection products, for injection products with complex details. In addition, the phenomenon of plastic debris accumulation on the nozzle or die head will also be improved. That is the reason why most products combined with processing aids will have uniformity in size, color, physical properties and durability.

2.5. Some other functions of processing aids

The processing aid will create a coating on the mold wall and prevent direct contact between the plastic mixture and the metal surface of the machine. Because PPA tends to move out and stick to the cylinder wall of the device as well as create a coating of about 2 - 20 micrometers covering the base plastic particles. Therefore, the friction force between the areas on the mold wall has been significantly eliminated and helps the manufacturer easily disassemble and clean after the processing process is finished. Not only the cylinder wall benefits from polymer processing aids (PPA), other parts such as: nozzle, roller, heating head or screw shaft.

Besides those main functions, PPA is popular and widely used partly because of its reasonable price and quality. Currently, the average price of standard polymer processing aids (PPA) is only from 7000/kg for both powder and granule forms, suitable for large-scale production processes. Therefore, if you pay attention, you can see that most household products, textiles, industrial nets, agricultural films and plastic pipes are combined with processing aids to increase their lifespan and meet the great demand of the market.

EuroPlas has introduced to you 5+ core functions of processing aids (PPA). Moreover, what customers need is a unit that provides and advises on how to use PPA effectively. We understand that and EuroPlas's customer care team and senior experts will not hesitate to support customers near and far in the most thoughtful and professional way.

.jpg)

Processing aids minimize clogging of extruders or plastic nozzles during production.

3. About EuroPlas

EuroPlas's mission is to enhance the competitive position of businesses through optimal raw material solutions. We are proud to be one of the largest filler masterbatch manufacturers in the world. EuroPlas has been steadily on the journey to make the Vietnamese plastic industry famous on the world map. We build a progressive mindset, constantly strive to improve the quality as well as diversify our plastic raw material product lines to be able to supply domestic and foreign markets.

In terms of products, EuroPlas supplies the following main lines: Bioplastics, plastic additives, Compound engineering plastics and Bio fillers. For services, EuroPlas provides consulting support packages and sustainable plastic production solutions for businesses. In particular, the core foundation for EuroPlas to confidently conquer the world market is thanks to the system of 7 factories in Vietnam and 1 in Egypt, which have worked together to supply approximately 0.8 million tons of plastic each year. Therefore, EuroPlas is a regular partner of thousands of factories in more than 95 countries around the world.

-c%C3%B3-gi%C3%A1-th%C3%A0nh-ph%C3%B9-h%E1%BB%A3p-v%E1%BB%9Bi-quy-m%C3%B4-s%E1%BA%A3n-xu%E1%BA%A5t-l%E1%BB%9Bn.jpg)

Polymer processing aids (PPA) are affordable for large scale production.

For processing aid additives (PPA), EuroPlas's team of experts suggests that businesses can use EMPA 05D in granular form. This is a type of PPA that can eliminate roughness and cracks on the surface as well as improve the gloss and physical properties of extruded plastic products. It also increases the extrusion speed, eliminating bottlenecks in the extrusion mold. It can be used in injection molding as well as blow molding or extrusion products.

EuroPlas has introduced to customers in detail 5+ outstanding functions and common applications of polymer processing aids (PPA). EuroPlas's R&D team will always strive on the journey of researching & developing plastic materials to provide the market with the best products and solutions. Please continue to accompany EuroPlas to update more knowledge & latest news about the global plastic market!