Plastic pipe system is always one of the important technical systems

Plastic pipe system is always one of the important technical systems in today's life. From manufacturing projects to civil projects, everyone needs a quality plastic pipe system. To operate over a long period of time and in a variety of conditions, it is essential to consider choosing the right material for the plastic pipe system. The following article will summarize different types of plastic pipes and provide a multi-dimensional view of the factors that determine the optimal plastic pipe for your project.

1. Types of plastic pipe

1.1. PP BaSO4 plastic pipe

PP BaSO4 plastic pipes always deliver amazing performance

PP BaSO4 plastic material is a line of synthetic materials made up of PP plastic and BaSO4. Thanks to outstanding properties such as durability, heat resistance, ease of shaping and friendliness to human health, this material is widely used in many manufacturing industries. Among them, pipes and fittings is one of the most popular applications of PP BaSO4 plastic.

PP BaSO4 plastic pipes are always the top choice for construction units because they bring many outstanding benefits. PP BaSO4 plastic pipes always deliver amazing performance thanks to the super durability of this material. These plastic pipes will possess hardness, and the rate of damage due to impact is almost very small. In addition, they operate durably in outdoor environments for long periods of time regardless of weather conditions. Some outstanding properties of PP BaSO4 plastic pipes include high heat resistance, light and easy-to-shape products, high abrasion resistance, and friendliness to humans and the environment.

Read more: Applications of PP BaSO4 composites in pipes and fittings

1.2. PVC plastic pipe

PVC plastic pipe has a reasonable price and is easy to install with only simple tools

PVC plastic, also known by its full name (polyvinyl chloride), is one of the perfect materials for pipe processing. PVC plastic pipe is known as the type of pipe that plumbers love most in a variety of projects. PVC plastic pipe has a reasonable price and is easy to install with only simple tools. In particular, PVC plastic pipe is inherently hard, durable and can be applied in many different environments including: installing drainage pipes, civil water supply pipes, irrigation pipes or even pipes conducted under high pressure conditions or underground. PVC material helps plastic pipes resist a variety of external agents such as corrosive acids, tree roots, and some abrasive substances.

A series of benefits that PVC plastic pipe brings include super durability, high corrosion resistance, shortened installation time, light weight, easy molding, reasonable price and especially they are also very environmentally friendly

1.3. HDPE plastic pipe

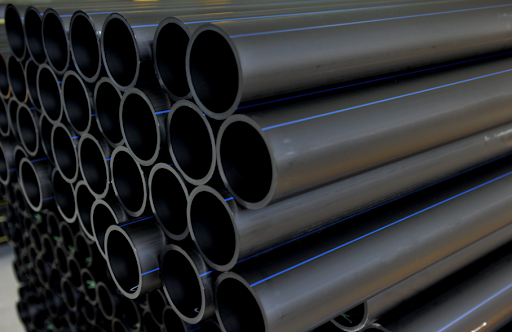

HDPE plastic pipe becomes one of the ideal choices for many different uses

HDPE material is known as high density polyethylene made from petroleum. Thanks to its high density in structure, HDPE plastic pipe becomes one of the ideal choices for many different uses. The applications of HDPE are very diverse, including the production of cosmetic bottles, water bottles, containers and even pipe installation.

Regarding pipe production, HDPE plastic pipe is one of the popular materials in most industrial and infrastructure construction fields. HDPE plastic pipe plays a role in applications such as drainage pipes, domestic water pipes, fire fighting system supply lines, rural irrigation, gas pipes, etc. It is easy to come across HDPE plastic pipes from industrial parks, residential areas to public pipeline systems. HDPE plastic pipe brings outstanding benefits to projects such as hardness, high resistance to most adverse impacts, lighter and easier to transport, and high resistance to freezing. They are very durable, helping to limit waste released into the environment.

1.4. ABS plastic pipe

ABS plastic pipe are known as not delaminating at extremely high temperatures

ABS plastic material's full name is acrylonitrile butadiene styrene. ABS plastic pipe is one of the popular pipe applications for many projects today. ABS plastic pipe meets the requirements of a variety of uses such as civil piping systems, wastewater pipes, and ventilation systems. They play an important role in removing wastewater from buildings and carrying it to the sewer lines of wastewater treatment tanks.

The outstanding properties of ABS plastic pipe are known as not delaminating at extremely high temperatures or sub-freezing temperatures, not rusting, and resistant to chemical and physical damage. In particular, ABS plastic pipes have high flexibility, allowing them to withstand a lot of pressure before being damaged or deformed.

2. Factors affected in choosing a plastic pipe

Due to the increasing demand for construction, many different types of plastic pipes are produced on the market. Before proceeding with a plastic pipe system installation project, we need to consider a number of factors to ensure optimization of the construction process.

Different materials will create different pressures in the pipeline environment

2.1. Materials are transported in pipes

The important thing in choosing a suitable plastic pipe is determining what material will be transferred in the pipe. There are many substances such as clean water, wastewater, sea water, crude oil, ammonia, air, nitrogen, or some specific corrosive liquids. Depending on the material being transported, we can compare the parameters of each different material. For example, we need to transport materials that are acidic or have heavy chemical composition. We should consider the corrosion resistance of the selected material to avoid damage during operation.

2.2. Temperature of the material to be transported in the pipe

There will be pipeline systems installed transporting substances with extremely high or extremely low temperatures. Depending on the temperature of the material, we can consider the appropriate plastic pipe. Ensuring pipes are made from materials intended for harsh applications will bring many benefits to the project. In case the temperature is too high, the material needs to have a high melting point so as not to contaminate the contained material by melting. On the contrary, if the temperature is extremely low, it is necessary to ensure that the material has a good low temperature resistance point to avoid cracking and damage.

2.3. Pressure of the operating environment

Different materials will create different pressures in the pipeline environment. For high pressure liquids you need to take advantage of materials that have high strength, high thickness and are designed to resist liquid pressure. Some materials require plastic pipes with good pressure resistance such as Ammonia, chlorine, Propane, Carbon dioxide, Nitrous oxide, Acetylene, Butane, Hydrogen, Helium, neon, Nitrogen, concentrated oxygen etc. Determining the pressure resistance of materials will help you limit many risks such as the risk of leaks, ruptures, flooding, fires, explosions, etc.

2.4. Easy to maintain

Different materials will have different maintainability. It is necessary to consider materials that are convenient for maintenance stages such as preventive maintenance, periodic cleaning maintenance, and emergency maintenance. Ensuring that materials can be easily maintained and inspected will make the system operate more safely. On the contrary, choosing a material that is not suitable for the operating environment can lead to a loss of time for maintenance and repair.

3. Conclusion

In conclusion, plastic pipe production materials on the market are increasingly upgraded. To choose a suitable plastic pipe, you need to consider many factors about material parameters, material properties and properties of the material that will be transported in the pipe. Careful consideration and selection of a suitable plastic pipe will help manufacturers increase the performance of the plastic pipe system and minimize damage during system operation.

4. About EuroPlas

EuroPlas will always be a great companion for your upcoming project. Our mission at EuroPlas is to constantly update and share useful materials knowledge with readers around the world. Visit the EuroPlas blog today to access a huge treasure trove of shared knowledge! We always have the criterion of providing customers with the most optimal material solutions in terms of both quality and price. In addition, EuroPlas provides a variety of typical materials such as filler and color masterbatches, additives, engineering plastic compound, bioplastics and bio fillers. You can find a variety of high quality and reliable options!