Transparent filler masterbatch is a functional filler. It's often made of barium sulfate and sodium sulfate at the nanoscale with a distinct particle size distribution. Special surface treatment and an ideal combination of carrier and additive help improve its optical properties. In PE, PP, and other polymer systems, this high-performance, affordable, and environmentally friendly masterbatch provides outstanding compatibility, dispersion, and light transmission.

Let's follow this article for more details on the topic!

1. What is Transparent Filler Masterbatch?

Transparent filler masterbatch is a mixture of plastic resins, additives, and inorganic powder. The use of this material ranges from 5 to 15% for end-product quality, but for some items, such as carry bags and liners, it can reach 60 to 70% to guarantee product qualities.

Transparent filler masterbatch combines plastic resins, additives, and inorganic powder.

Without compromising their clarity, transparent filler masterbatch aims to lower manufacturing costs, improve mechanical qualities, and lengthen the lifespan of plastic items.

2. Advantages of Using Transparent Filler Masterbatch

Transparent filler masterbatch offers several benefits to final products, including:

- Improved transparency and aesthetic appeal

This material is perfect for high-visibility applications like packaging films and display items. It gives plastic items a glossy appearance and enhances surface smoothness, creating an advantage in consumer-facing sectors like retail and packaging.

- Enhanced mechanical properties

By adding substances like sodium sulfate or barium sulfate, transparent plastic filler improves the mechanical characteristics and visual appeal of plastic items. These fillers provide plastic parts with more durability and tensile strength, which increases their resistance to deterioration. This is especially advantageous for sectors like consumer goods, construction, and automotive, where strength, flexibility, and clarity are equally important.

By lowering the amount of costly virgin polymers used in plastic compositions (but without sacrificing product quality), transparent fillers provide financial benefits.

Transparent filler masterbatch is versatile and can be used in many applications, including flexible films, rigid packaging, automotive parts, household items, and medical equipment. Because it is compatible with different plastic resins, such as polyethylene, polypropylene, and polyvinyl chloride, producers may use it in a variety of product lines.

Transparent filler masterbatch offers various benefits

3. How to Choose the Right Transparent Filler Masterbatch

Businesses should consider several factors before choosing the most suitable transparent filler masterbatch. They are:

- Requirements of end-use applications

First, you should identify the final product types along with their specific needs. For example, food packaging usually prioritizes highly transparent and food-safe fillers. Meanwhile, if your product is automotive components, you may want to focus on a material that can provide great impact resistance.

With transparent filler masterbatch, clarity level plays an important role in determining which material is for what purpose. For example, clear packing will require both high transparency and high filler concentrations.

- Compatibility of materials

The kind of resin, such as engineering plastics or polyolefins, determines which base resins are the most suitable. Verifying the filler's thermal stability at the processing temperatures required for the particular application is essential since incompatible fillers may degrade or undergo mechanical changes.

Different filler types offer different exceptional advantages:

+ The talc filler masterbatch improves the hardness, durability, anti-slip qualities, and anti-clumping features of plastics. It produces a smooth surface without the use of anti-block additives, enhances printing capabilities, boosts hardness and durability, and lessens the need for corona treatment.

+ Because of its strong mechanical qualities, stability, durability, high transparency, and great gloss, sodium sulfate filler masterbatch is utilized extensively in a wide range of products and production processes. When used as a partial replacement for specific plastic raw materials, it offers better performance, lowers production costs, and is ecologically beneficial. Additionally, Na2SO4 plastic filler is resistant to high temperatures, acids, and alkalis.

+ Barium sulfate filler masterbatch improves the density, surface smoothness, and opacity of plastic products. It also provides exceptional chemical stability, UV resistance, and heat tolerance, making plastic items appropriate for weather resistance and durability.

Always consider your budget before buying. However, keep in mind that sometimes you need to pay the price to get the ideal product.

Look for trustworthy, transparent filler masterbatch suppliers, such as EuroPlas, to ensure you receive high-quality products. These companies usually have strict quality control measures and good customer service.

4. Applications of Transparent Filler Masterbatch

Transparent filler masterbatch is a popular material across industries since it improves base resin qualities without sacrificing clarity.

Application of transparent filler masterbatch

Some of its applications are:

- Packaging: Fillers are widely used in food packaging, cosmetic and personal care containers, and household storage products. They provide clarity, allowing users to see the content inside. Besides, they have great barrier properties and reduce material costs for manufacturers.

- Toys: Semi-transparent or clear toys require a transparent filler masterbatch for aesthetic and safety requirements.

- Automotive components: The fillers are suitable for transparent or semi-transparent exterior parts since they offer the necessary clarity and strength. Meanwhile, interior components, such as trims or dashboards, call for a clear and aesthetic finish. Using a transparent filler masterbatch can satisfy that requirement.

- Medical equipment: Thanks to their clarity and safety properties, the fillers are used in disposal products (transparent tubing, IV bags, and syringes) and diagnostic equipment where visibility for monitoring is required.

- Construction: Clear panels are essential for light transmission in windows, skylights, and other transparent building materials. Manufacturers can use transparent filler masterbatch to meet that requirement.

5. Conclusion

Transparent filler masterbatch offers better mechanical qualities, adaptability, and affordability, making it an essential component in the production of plastics.

The use of transparent filler masterbatch is expected to increase to meet the growing demand for economical and environmentally friendly solutions. The future plastics manufacturing process will not be without this material.

6. Introducing Transparent Filler Masterbatch from EuroPlas

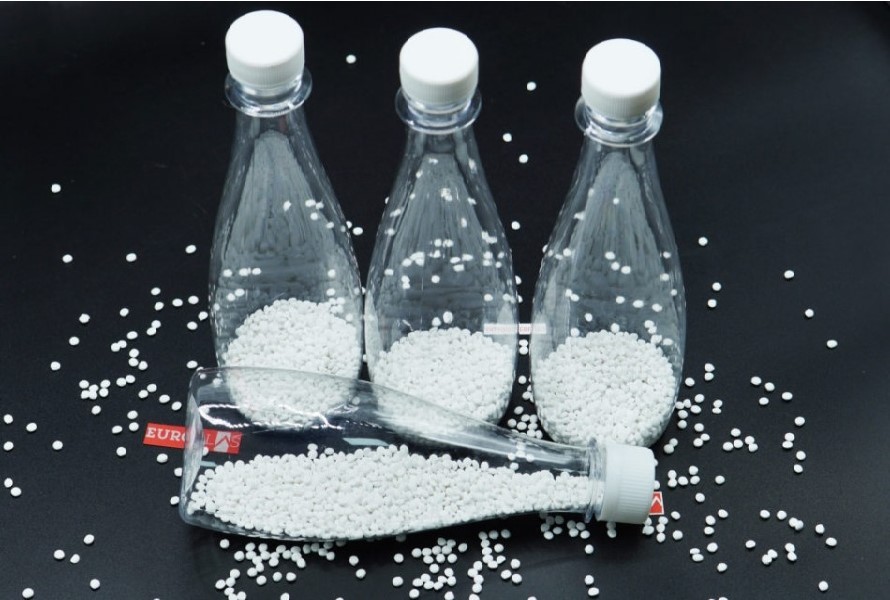

High-quality transparent filler masterbatch from EuroPlas

Transparent filler masterbatch from EuroPlas is a mixture of plastic resins, additives, and inorganic powder. It improves the distortion temperature, elongation fastness, light resistance, physical durability, glossiness, and transparency of the final product. It's a trusted method for our clients to lower manufacturing costs and enhance mechanical qualities.

EuroPlas is always open to cooperation. Contact us!