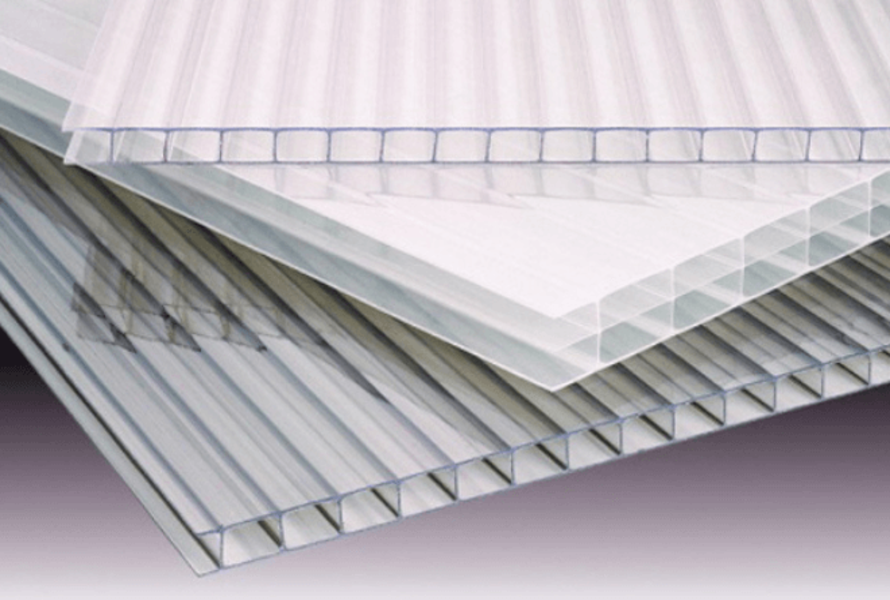

Transparent plastic panels are produced from a variety of types such as: PVC, Mica, Acrylic, Polycarbonate. Therefore, transparent materials possess outstanding advantages, specifically: fire resistance, heat resistance, stable durability and high practicality in many fields or heavy industries. Choosing to use transparent plastic sheets depends on different purposes. In this article, EuroPlas will introduce to you the 4 most popular transparent plastic application areas.

1. What is a transparent plastic sheet?

In fact, transparent plastic panels are created from the characteristics of other popular plastic substrates such as: HDPE Plastic, Acrylic Plastic, PETG Plastic.

Transparent plastic sheets are divided into two types: thermoplastic and thermoplastic. The product's characteristics are colourless, odourless, transparent on both surfaces and easy to receive light.

Because it possesses the advantages of other plastic substrates, transparent plastic panels are considered a construction material with chemical resistance, surface durability, flexibility in applications, electrical insulation and Heat resistance at a stable level for a long time.

Currently, to improve the structure of transparent plastics, manufacturers will inject them with specialised plastic additives such as: fire retardant, anti-aging additives, anti-UV plastic additives, etc. Therefore, transparent plastic sheets are used in construction, manufacturing, design or heavy industries.

In the next section, EuroPlas will send you the Top 10 most common applications of transparent plastic sheets in life. Do not miss it!

Transparent plastic sheets are divided into two types: thermoplastic and thermoplastic

2. Common application areas of transparent plastic sheets

Transparent plastic panels possess 4 basic characteristics: UV resistance, mechanical durability, ease of moulding as well as safety for human health. Therefore, the product is applied in many fields such as: Construction, manufacturing, furniture,... Refer immediately to 4 fields where transparent plastic is widely applied.

Application of transparent plastic

2.1. Construction Field

Transparent plastic panels are used as roofing panels in house premises or in window areas, skylights, etc. because they are not only resistant to UV rays but also easily receive light. Therefore, your home is not only protected from the sun's toxins and minimises temperature, but is also always well-ventilated.

Transparent plastic sheets are also used as awnings in public areas such as parks, swimming pools, etc. They provide safety by helping your skin avoid direct exposure to toxic UV rays. Harmful, minimising conditions: sunburn, skin irritation, skin cancer,...

Use transparent plastic sheets as roofs

2.2. Interior design

Transparent plastic panels are applied to soundproof walls used in modern residential areas, commercial centres, highways or train tracks.

Depending on customer requirements, the manufacturer will adjust the thickness of the transparent plastic sheet. However, standard parameters will be from 1mm to more than 3mm.

In particular, during the past epidemic season, the influence of transparent plastic sheets was shown more clearly. They are mass produced into partitions in office areas, on public transport, and canteens to ensure distance and safety for the community.

Besides, in modern design style, people take advantage of the transparent color of the product to line the walls and increase the soundproofing ability of the building because the soundproofing frequency of the product reaches nearly 31db.

Transparent plastic panels are used in interior design in office areas

2.3. Heavy industry sector

Standard transparent plastic panels can resist the penetration of strong acid particles and solvents, combined with high heat resistance from minus 20 degrees Celsius to about 120 degrees Celsius, the product is a perfect choice. Perfect for heavy industries.

They are produced into cement and chemical tanks in large industrial parks. Besides, transparent plastic sheets are also produced in air processing systems, industrial fans or large industrial cabinets.

\

\

Transparent plastic panels have reasonable prices and colors suitable for public spaces

2.4. Security field

You will be very surprised to hear that transparent plastic panels made from Polycarbonate plastic can withstand 25 times better force compared to conventional glass or plastic". Therefore, they are used in the police and military to produce bulletproof glass panels for crime prevention and protection of social order and security.

Besides, they are also quite good substitutes for tempered glass for use as glass doors in high-rise buildings, cars, large container trucks or warehouse areas.

In particular, transparent plastic sheets can be processed into many different shapes and sizes to fully meet the needs of customers. Therefore, the choice of using transparent plastic is increasingly popular. Most transparent plastic panels are derived from type 5 plastic, ensuring full safety indicators for consumer health and easily decomposing without affecting the environment.

On the market, most popular plastic substrates can become raw materials for the production of transparent plastic sheets. In the next part, EuroPlas will introduce to customers the Top 4 types of specialised plastic substrates in the production of transparent plastic panels!

Transparent plastic sheets are used as curtains in industrial parks

3. Common plastic materials used to produce transparent plastic sheets

Top 3 popular plastic substrates in the production of transparent plastic sheets. As follows:

3.1. Acrylic transparent plastic sheet

Plastic belongs to group number 7 because acrylic is more difficult to recycle than regular plastics. However, Polymethyl methacrylate is the most popular Acrylic plastic on the market.

Acrylic plastic has the following 3 basic characteristics:

-

Acrylic plastic is not only easy to shape into moulds but also can withstand high temperatures ranging from minus 30 degrees F to nearly 200 degrees F, making it very suitable for heavy industries.

-

The surface of Acrylic plastic is considered to be flat, stable and shiny. Therefore, when combined with engraved colours and light-enhancing plastic additives, it will help light pass through easily.

-

Besides, acrylic transparent plastic panels are also widely used in the field of interior design because of their ability to resist water and mould under bad weather conditions for long periods of time.

-

Moreover, transparent plastic panels made from Acrylic plastic are also used to build greenhouse systems in agriculture, aquarium glass surfaces or outdoor advertising signs.

Acrylic transparent plastic sheet

3.2. Transparent plastic sheet from HDPE plastic

HDPE transparent plastic sheets possess the following 4 outstanding advantages:

-

The bearing surface and tensile strength of HDPE is at least 21 Mpa with a density of 940kg / m3 because of the thickness and the connection of molecular density in the chemical structure. Therefore, HDPE transparent plastic panels have a hard surface, high strength and heat resistance.

-

Besides, the Ethylene bound in the molecular structure of HDPE plastic allows them to resist strong active ingredients and strong acid molecules. Therefore, transparent plastic sheet products can resist abrasion and are used in the chemical industry with products such as chemical tanks, industrial fans,...

-

The melting and decomposition temperatures of HDPE plastic are 142 degrees Celsius and 300 degrees Celsius, respectively. Therefore, HDPE transparent plastic sheets are used for outdoor products or in large industrial zones.

-

Finally, HDPE transparent plastic sheets are used to make glass panels and partitions in high-rise buildings and office areas because their weight is only from 0.93 to 0.97g/cm3 so their tensile strength is very impressive.

HDPE plastic substrate is also on this list because its ability to impact the environment as well as consumer health is almost zero. Although they are also quite difficult to recycle, the effects of weather, temperature, and environment cannot cause them to produce toxins.

Hdpe transparent plastic sheet

3.3 Type of Polycarbonate transparent plastic sheets

Polycarbonate plastic base is created from the synthesis of the reaction between bisphenol A (BPA) and phosgene to create Carbonate groups. The chemical structure of Polycarbonate is quite special because of the repetition of the carbonate group.

The chemical structure of Polycarbonate-based transparent plastic sheets has an average density because 1.2g to 1.4g/cm3 is the average density of Polycarbonate. Therefore, the surface of this type of plastic is not too hard, but it still ensures heat resistance, UV protection and flexibility.

In terms of heat resistance, 220 degrees Celsius to 250 degrees Celsius is the melting point of Polycarbonate. Therefore, transparent plastic sheets made from Polycarbonate plastic are easy to mold and shape to serve many different industries.

In addition, it is the continuous repetition of Carbon groups that helps Polycarbonate plastic resist the attack of strong acids, minimising surface wear. Therefore, Polycarbonate transparent plastic sheets are also used in the chemical industry.

Besides, Polycarbonate plastic is chosen to produce transparent plastic because it has high elasticity. The elastic modulus value of Polycarbonate plastic ranges from 2,000 to 2,400 megapascals (MPa). This is the appropriate parameter level to help Polycarbonate Plastic have the ability to resist deformation when exposed to strong impacts.

EuroPlas has sent to customers the Top popular transparent plastic materials.

4. Introduction to EuroPlas

EuroPLas is proud to be one of the largest Filler Masterbatch manufacturers in the world and brings optimal bioplastic products to help businesses improve their competitive position in the market.

EuroPlas' mission is to provide optimal, environmentally friendly material solutions to contribute to increasing competitive advantages for businesses. Therefore, EuroPlas constantly strives to become the world's leading enterprise in the field of supplying plastic raw materials.

Professional and dedicated staff at EuroPlas

Currently, EuroPlas has 7 factories with a scale of dozens of hectares in 6 provinces and cities: Ha Nam - Yen Bai - Hai Phong - Nghe An - Long An and Ho Chi Minh City. The factories are equipped with modern production lines that meet European standards, so each year we are capable of supplying up to 0.8 million tons to meet the great demand of customers nationwide.

In addition, EuroPlas is also a strategic partner of thousands of factories in more than 95 countries globally. Established since 2007, EuroPlas has been proving its capabilities with a team of dedicated and professional personnel.

Behind a pioneering EuP with optimal material solutions is a team of leading experts and thousands of staff and technicians who work day and night to bring the best quality products to customers. The year 2023 marked an extremely important milestone for the entire EuroPlas team when it inaugurated its first factory in Egypt.

EuroPlas production factory system

The above article mentioned the definition, characteristics and common applications of recycled plastic beads in life. Please continue to accompany EuroPlas to update the latest news about materials in general and bioplastics in particular!

EuroPlas's first factory in Egypt