Using a biofiller in manufacturing is gaining popularity due to its environmental benefits. The performance of plastic items can be improved by using these biodegradable elements in place of traditional fillers.

This article will discuss this material in detail, analyze its advantages, and give some examples of its applications. Scroll down for more!

Read more: What is plastic? Everything you need to know about plastic

1. Overview Of Biofiller

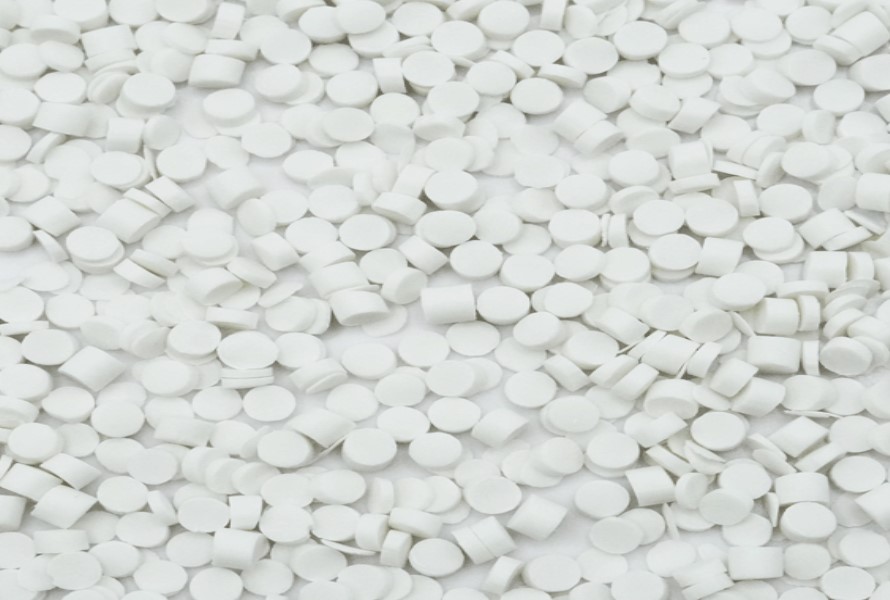

In theory, biofiller is a mixture of bioplastics, specialized fillers (calcium carbonate powder, talc powder, barium powder,...) and additives with different formulas to fully meet the requirements of the finished product.

There are more and more plastic products made from biofillers. The material is expected to replace the traditional fillers and lower the carbon footprint on the environment.

Using a biofiller is a sustainable way to lower plastic waste and carbon emissions. It's a desirable option for manufacturers looking for sustainable solutions since it not only enhances the mechanical and thermal qualities of plastics but also solves issues with disposal and environmental deterioration.

Read more: What is bio filler masterbatch and how is it applied in the plastic industry?

2. What Are The Applications Of Biofiller?

You can find the applications of biofiller in numerous sectors, including:

Biofillers are present in the production of biodegradable films, containers, and molded products. Using it in packaging can satisfy performance requirements. Besides, the bio-based packaging also features aesthetic appeal.

Furthermore, bio-based composites enable packaging to break down more quickly in composting conditions, minimizing waste sent to landfills and addressing the plastic waste issue.

The consumer goods market is changing quickly due to the adoption of biofillers in many products, including furniture, kitchenware, and electrical casings. Bio-based polymers provide aesthetic appeal and sustainable properties. Manufacturers can customize the biofiller to meet the final product's color and texture requirements.

In the field of medicine, biofillers are being investigated for usage in biodegradable medical devices such as implants and sutures. Sutures created from bio-based materials can disintegrate in the body over time, removing the need for removal and infection risk. These bio-based products may safely break down in the environment, which lowers waste and encourages sustainable medical procedures.

Biofillers are becoming popular in construction for flooring, insulation, and ornamental components since they provide better thermal resistance and acoustic performance. For example, natural fiber-reinforced composites, as an ecologically benign alternative to typical fiberglass insulation, offer superior thermal insulation.

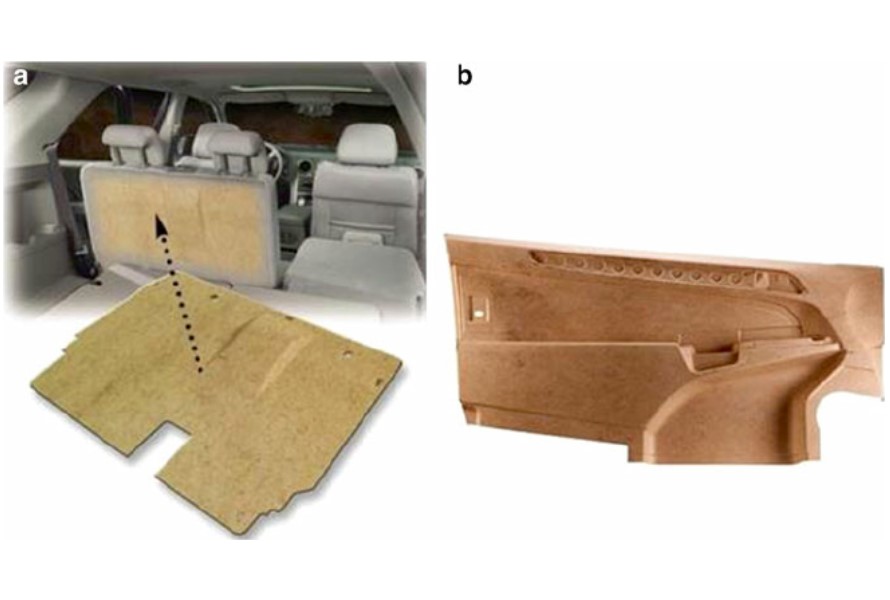

Biofillers are being used more often in the automotive sector to lower emissions and increase fuel efficiency. They have the potential to reduce greenhouse gas emissions and fuel consumption by decreasing weight without sacrificing strength. Bio-composite dashboards, interior panels, and natural fiber-infused non-structural body elements are examples of innovations.

Textile products that contain biofillers have better breathability and moisture absorption. Combining synthetic and natural fibers, such as cotton or hemp, helps improve sustainability without sacrificing comfort or durability.

3. Advantages Of Using Biofillers

Using a biofiller offers both performance-related and environmental benefits:

Biodegradable materials can benefit the environment. After the end of the products, the biofiller components can break down more quickly in natural settings, reducing landfills.

Because biofillers are composed of renewable resources and rely less on fossil fuels, they provide a sustainable alternative to traditional plastic manufacture, helping to slow down global warming.

Some biofillers can contribute to the lightweight properties of the products, which is especially necessary for packaging and transportation. By lessening the weight, the products require lower shipping costs and less energy consumption during transport.

- Enhanced mechanical properties

A biofiller can be customized to improve the plastics' mechanical properties, such as stiffness, strength, impact resistance, and overall performance.

Although the initial investment in biofillers may be more than that of standard fillers, over time, the savings from less material consumption, longer product lifespans, and lower disposal costs may exceed these expenses.

Since biofillers may be used in a variety of formulations, their versatility enables producers to design distinctive products that meet certain performance needs. It promotes innovation and distinction in the market.

4. Conclusion

Biofillers are revolutionizing the plastics production sector by enhancing product performance and tackling environmental concerns. They are used in consumer items, medical gadgets, automobile parts, and packaging, among other industries.

The tendency to use a biofiller in manufacturing is growing as factories are reacting to customer demand for greener products. By incorporating biofillers, businesses may contribute to the reduction of carbon emissions and plastic waste, improving global health.

5. About EuroPlas' Biofillers

As one of the leaders in the masterbatch world, EuroPlas acknowledges and understands the necessity of a green solution for plastic manufacturing. Thus, we've created our Biofiller, a cost-effective material for bioplastic end-products.

As one of the leaders in the masterbatch world, EuroPlas acknowledges and understands the necessity of a green solution for plastic manufacturing. Thus, we've created our Biofiller, a cost-effective material for bioplastic end-products.

We offer the BIOMates series, combining bioplastic, modified CaCO3 powder, and dispersion aids. It is an economical method of processing bioplastic materials and increases the competitiveness of the final product by improving qualities like gloss and film toughness.

To meet the needs of different applications, EuP has created three distinct biofiller product lines: BiOMates 01, BiOMates 02, and BiOMates 3. BiOMates are ideal for the production of eco-friendly goods such as single-use plastic extrusion, injection molding, and biodegradable packaging.

For more information, contact EuroPlas!