PEEK implant is a leading choice in many medical applications, including orthopedic, spinal and cardiovascular surgeries, thanks to the exceptional qualities of the material. Many PEEK medical devices are designed and improved, increasing its popularity in the medical field. It is now the main rival to titanium implants and has assumed the top position in several areas.

Let’s dig into the topic with EuroPlas right away!

Read more: PEEK plastic: Definition and Application

1. Brief overview of PEEK implants

PEEK implant is used in numerous medical fields, such as orthopedics, spinal surgery, cardiovascular devices, dental implants, etc. The mechanical strength, radiolucency and biocompatibility of PEEK make it ideal for these applications; thus, increasing its popularity and demands.

PEEK technology has been improved with lots of advancements. For example, the modified formulations with properties like osseointegration and antimicrobial capabilities have been developed, helping decrease the infection risk in surgery. Furthermore, PEEK implants that are patient-specific can now be fabricated thanks to 3D printing, offering exact optimization and customization for each patient's requirements.

Two most popular applications of PEEK implant are in orthopedic and spinal surgery.

- PEEK is becoming more and more popular in orthopedics because of its radiolucency, bone-like modulus, and low weight. It is perfect for applications including partial or total replacement, knee and hip arthroplasty, and maintaining joint function. PEEK's radiolucency makes it possible to read images accurately and manipulate joints and limbs with ease. Because of its lightweight design, which also improves patient comfort, it is a recommended option for orthopedic treatments.

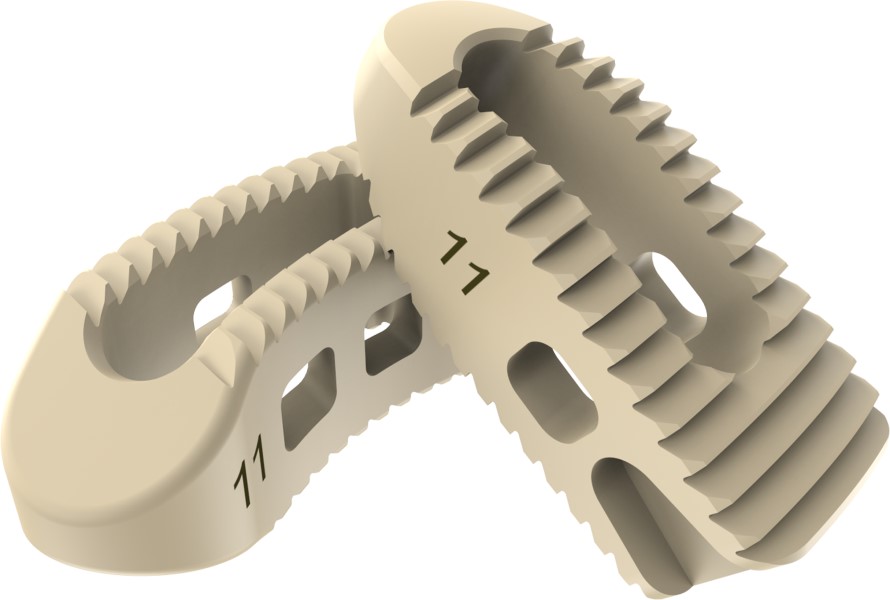

- PEEK is a widely used material for spinal implants because of its safety and effectiveness. Patients with scoliosis, spondylolisthesis, spinal stenosis, and degenerative disc disease are treated with it during procedures. PEEK is a top option for spinal implant treatments because of its ideal modulus and radiolucency. Its radiolucency enables surgeons to track healing while its modulus guarantees that the implant supports weight like natural bone. Additives can be added to PEEK to improve contrast.

PEEK in spinal implant

2. Versatility in Implantation

PEEK implant has inherent features that allow for customization to match patient-specific needs, offering extraordinary adaptability in implantation. The biocompatibility of PEEK makes it ideal for various medical scenarios without creating any adverse reaction to the body. It’s suitable for different physiological needs and anatomical structures.

The option to customize PEEK implants is one of their biggest benefits. 3D printing is one example of an additive manufacturing process that makes it possible to fabricate implants that are customized for each patient's anatomy. Surgeons can optimize surgical outcomes and lower the risk of problems by designing implants that exactly suit each patient's unique anatomy using patient imaging data, such as CT or MRI images.

Moreover, PEEK is a good option for load-bearing applications due to its mechanical qualities, including a high strength-to-weight ratio and fatigue resistance. It indicates that it can sustain the strains and stresses placed on weight-bearing bones or joints, offering support and stability.

3. Benefits for Patients

PEEK implant provides patients with a number of advantages, such as:

- Low risk of adverse reactions

Thanks to the biocompatibility of PEEK, the body can accept it well and there's little chance it will cause an allergic reaction or an immunological response. Thus, a list of problems, such as infection, inflammation and implant rejection can be reduced, and patients will have better results and permanent implant success.

- Reduced imaging interference compared to traditional implants

In contrast to metallic implants, PEEK implants have radiolucent properties. It means they’re transparent to imaging modalities, including X-rays, thus, eliminating the metal artifact interference and enabling a sharper image in medical imaging. The more precise the image, the more accurate surgical planning. In turn, the patient care is improved.

4. Future Trends and Research

PEEK plastic has the potential to completely transform medical implants by providing patients with individualized, secure, and long-lasting solutions. It can be a vital material for various life-saving and life-enhancing medical devices, thanks to its wide range of properties and fabrication capabilities.

By 2030, PEEK medical components and implants are projected to generate over $1 billion in global sales, growing at a rate of more than 25% annually. The material is anticipated to replace metal in sterile, single-use surgical equipment such as forceps and blades.

These implants also save long-term expenditures by a decrease in failures and revision surgeries, even though they have higher initial prices. PEEK medical devices will be more popular because it enables patient-specific implants to be produced in inexpensive batches using 3D printing.

3D printing in PEEK implant

5. Conclusion

Because of the mechanical characteristics, radiolucency, and biocompatibility, PEEK implant is used in many medical fields, such as spinal, orthopedic, and dental procedures. They help with spine surgery, support joint replacements, and enhance appearance. Its adoption transforms healthcare by delivering safe, efficient, and customized solutions while lowering adverse responses, improving treatment outcomes, and facilitating sharper imaging.

Above are the main uses of PEEK implants. We hope this article is useful knowledge for you. In addition, EuroPlas also provides other types of engineering plastics besides PEEK plastic, such as:

5.1. PA6 & PA66 Blend Compound

PA6, PA66 blend compound is a combination of PA6 resin and elastomer, used in the automobile and motorcycle industries for applications like roller bearings, office equipment, carburetors, and fuel tank lids. EuroPlas plastic compound, with 15 years of industry experience, offers a stable and quality raw material for precision, mechanical strength, and improved usability and durability. It can be directly processed without any materials, is tailored to end-products' requirements, and has good elasticity and high impact strength.

5.2. PA6& PA66 Glass Fiber Compound

PA66, PA6 glass fiber compound is a blend of PA resin and glass fibers, offering excellent toughness, wear resistance, chemical resistance, high heat deflection temperature, mechanical strength, stability, electrical insulation, and easy molding. It is widely used in producing gears, bearings, drive belts, carburetor components, computer components, and household electrical components. It can be directly processed, customized, and enhances impact resistance and thermal durability.

5.3. PP Flame Retardant Compound

PP-FR compound is a mixture of polypropylene resin and halogen/non-halogen flame retardant, used in the electronic industry and fireproof components production. It has different levels of UL94-standard flame retardants, such as 5VA, 5VB, V0, V1, and V2. PP compounds are crucial for electricity, electronics, construction, building supplies, cables, circuit boards, and plastic coverings in the electrical and electronic sectors. EuroPlas offers PP flame retardant compounds with various levels of UL94-standard flame retardant, allowing direct processing without materials required and preventing fire spread on plastic surfaces.

5.4. PP Conductive Compound

PP conductive compound, a blend of PP resin and carbon black conductive, is a popular material in various industries like packaging, construction, and home appliances. Its lightweight and easy-to-work-with properties make it ideal for manufacturing electronic components, cable jackets, and electrical equipment housing. EuroPlas conductive polypropylene is trusted for its high quality and cost-effectiveness, offering all functions in one material.

If you want to know more about EuroPlas products, don’t hesitate to contact us right now!