You can open and close the lid of your shampoo bottle hundreds of times without breaking it, or your kids throw and chew their toys, but they still survive with little damage. It's because these products are made of an excellent resilient material named polypropylene plastic.

PP plastic is well-known for its durability and resistance to various external factors. That's why it's an ideal choice for many daily items such as housewares, utensils, cars, toys, sportswear, and plastic pallets, and it's even used in textiles, laboratory work, and medical equipment production.

1. What is Polypropylene (PP) Plastic?

Is polypropylene a thermoplastic? Yes, Polypropylene or PP (its chemical formula is (C3H6)n) is a thermoplastic formed from the polymerization of propylene. Polypropylene molecular weight is 1,000,000 g/mol, and the density of PP is from 0.895 to 0.93 g/cm3.

This plastic was first polymerized in 1951 and became widespread in commercial production during a short period. Nowadays, plastic polypropylene is one of the top-produced in the world. The global market of polypropylene PP is estimated to be 70 million tons in 2021 and is anticipated to experience potential growth in the next 10 years.

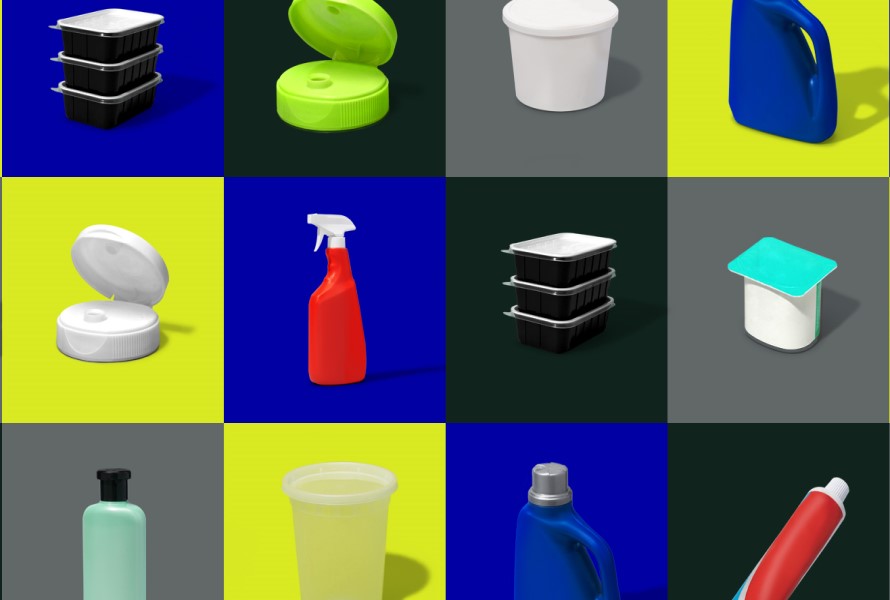

Polypropylene plastic is a common material

This synthetic resin has many outstanding thermo-physical properties. Properties of polypropylene include translucent, tough, semi-rigid, integral hinge properties and good fatigue, heat, and chemical resistance. PP polypropylene has two main types: homopolymers and copolymers. The former is suitable for pipes, packaging, textiles, electrical applications, and medical components. The latter is ideal for making soft and hard plastics, toys, rubber tires, insulation materials, water pipes, electronics, pharmaceuticals, etc.

2. All About Polypropylene Material Properties

2.1 Polypropylene Tensile Strength

Polypropylene plastic has a structure with a good tensile strength of about 4,800 psi. It explains why this thermoplastic can withstand quite heavy loads though it's lightweight, rendering it a desirable impact tolerance. This property makes it an ideal material for packaging.

2.2 Polypropylene Yield Strength

The yield strength of polypropylene is approximately 33MPa. It's the point where PP will start to deform in a plastic fashion. Before reaching the yield strength, polypropylene is elastic. The material will return to its original length if the strain is applied within the flexible portion.

2.3 Polypropylene Chemical Compatibility

Polypropylene chemical resistance is well-known, especially compared to "regular" plastic polyethylene. Since many chemicals don't react with it, PP is an excellent choice for applications requiring resistance to many acids, alkalines, and organic solvents, such as plastic pallets and chemical containers.

Its anti-chemical corrosion is also perfect for bleaches, cleaning products, and first-aid staples. However, polypropylene plastics are not good with aromatics, chlorinated hydrocarbons, and oxidizing acids.

2.4 Polypropylene Food Safe

Pp plastic food containers

Is polypropylene food safe? The answer is yes. It's a great FDA food-grade plastic. It's not only moldable, lightweight, and strong but also has a high melting point, allowing it to be used in microwaves and dishwashers. So, you don't need to have doubts about polypropylene food safety.

2.5 Polypropylene Heat Resistance

The polypropylene temperature range is quite high. It can operate at the temperature of 180°F (82.2°C). A very hot environment may not be suitable for the material, and it can compromise its performance values. However, using it within this temperature limitation is good enough for most applications in natural environments. Outdoor signage is an example.

If the polypropylene temp range is more than 180°F, the material can't perform, but it will not melt until it reaches the melting temperature of 327°F (163.8°C).

2.6 Polypropylene UV Resistance

Is polypropylene UV resistant? Unfortunately, you can't count so much on this plastic in this case. It can't tolerate the ultraviolet wavelengths of 290-300, 330, and 370 nm (nanometers). These points are the spectra maxima of PP. Exposure to these UV rays causes the material to degrade.

Therefore, though polypropylene plastic has excellent mechanical strength and great chemical resistance, you'd better not prolong its staying under direct sunlight. Since it's not easy to put a coating layer on the material, the best solution is to keep it totally away from sunlight.

3. Introduction of PP Engineering Plastic Compound

PP engineering plastic compound is a blend of PP resin and special reinforcing agents such as flame retardant additives, conductive black carbon, talc mineral, fiber/glass beads, etc. Depending on the requirements of the final product's characteristics, manufacturers will choose what reinforcements to combine.

PP has many outstanding properties

Therefore, besides the primary properties of traditional polypropylene, PP engineering plastic compound also possesses extra attributes suitable for the finished applications. PP compounds in particular and all kinds of compounds in general are used to directly produce finished products without mixing with other materials, allowing businesses to have simpler and more time-saving production processes, thus, improving their productivity.

| Name |

What is better? |

Applications |

| PP glass fiber compound |

Less shrinkage, better stiffness, impact, and heat resistance |

Car doors, kettle handles, rice cooker covers, etc. |

| PP glass bead compound |

The improved wear resistance of the final products, minimized cracks, and shrinkage |

Home appliance, interior, and automotive decoration |

| PP talc compound |

Reduced shrinkage, less risk of being stretched due to temperature, better flexural strength |

Outdoor equipment, motorcycles, and cars |

| PP BaSO4 compound |

Reduced deformation, enhanced stability, hardness, and gloss |

Sanitary ware, water purifiers, vacuum cleaners, rice cookers, etc. |

| PP conductive compound |

Greater stability and conductivity of the end products |

Household appliances, pumps, pipes, ESD film, etc. |

| PP flame retardant compound |

Better flame retardancy |

Household electrical and electronic equipment |

The Bottom Lines

Polypropylene plastic is an ideal material especially useful in various industries. Thanks to the polypropylene strength, rigidity, high melting point, and chemical resistance, you can see its applications almost everywhere, such as packaging, toys, furniture, fibers and fabrics, automotive parts, and medical and industrial applications.

In addition, polypropylene recycling is also possible, making this plastic a cheap and environmentally friendly material. If you need support with PP engineering plastic compounds,

contact EuroPlas right now.