Thermoplastic paint is widely used in pavement markings since it offers excellent visibility even in bad weather. It's also an affordable and long-lasting solution used in business parks and playgrounds.

The material obtains many thermoplastic properties, making it ideal for outdoor marking applications. Let's dig into the article to learn more about this topic right now!

Read more: Thermosetting vs Thermoplastic: Which one to choose?

1. Definition of thermoplastic paint

Thermoplastic paint, or hot melt marking paint, is made from powdered paint heated to 200°C (392°F) to form a bright, reflective, and wear-resistant polymer layer. Since this paint becomes quite slippery in rainy and snowy conditions, resulting in wheel slippage and accidents, it is frequently mixed with gritty fillers and reflecting glass beads to enhance its anti-skid properties. This paint can be made in any color and is appropriate for parking lots, factory walkways, and expansive anti-skid areas on roadways and pedestrian walkways.

2. Components of thermoplastic paint

Based on C5 resin and combined with pigments, aggregates, glass beads, additives, and solvents, road marking paint is a commonly used marking material for asphalt and cement pavements. Its composition ratio can be adjusted according to local temperature, road conditions, and specifications.

- Resin: It's the main component in thermoplastic paint, offering adhesion and binding other ingredients.

- Pigments: The color of the paint is achieved by adding pigments. Although various colors may be used for certain purposes, white is the most frequently used color for road markers.

- Glass Beads: When headlights shine on road markings at night, glass beads provide retro-reflectivity, which is essential for visibility.

- Fillers: Fillers like titanium dioxide or calcium carbonate are applied to increase the paint's opacity and lower costs.

- Plasticizers: Plasticizers are used to increase paint's flexibility and surface adherence.

- Curing agents: These substances hasten the solidification and curing of paint after application.

3. Why choose thermoplastic paint for pavement markings?

Pavement with thermoplastic paint

Thermoplastic paint benefits the road marking industry since it has many advantages. They include:

- Safety: Thermoplastic road markings enhance road safety. Their highly reflective properties make them visible and, hence, easier to see on crowded roads with limited vision. By applying them in layers to produce rumble strips, you can reduce accidents and avoid collisions by raising drivers' awareness and alerting drivers to possible danger zones. You can often see their applications on crosswalks, bicycle lanes, and airport markings.

- Durability: Thermoplastic road markings are long-lasting, low-maintenance alternatives for paint and other materials. They can be applied to any road surface and feature glass beads for increased skid resistance. Frequent maintenance and repairs are minimized as thermoplastic paint can be visible and legible for extended periods, even under heavy traffic and harsh weather conditions.

- Customizable and multiple applications: The paint can be customized to meet certain requirements of various applications, including roads, sports courts, playgrounds, and parking lots. It can be used to produce a wide range of markings, such as arrows, symbols, and text, and is available in many colors.

- Easy to apply and maintain: Thermoplastic paint is simple, easy to use, and weatherproof, making it a skid-resistant option for road marking. It is ready for use 30 minutes after application, guaranteeing minimal downtime and avoiding traffic delays. It's also a low-maintenance choice with less repainting frequency and can be simply cleaned with water.

- Environmentally friendly features: The paint is a safer and more environmentally friendly option for road marking because it is reusable and doesn't contain any hazardous volatile organic compounds (VOCs), reducing the waste that comes with road marking.

- Cost-Effective solution: The product is a cost-effective option since it offers long-lasting nature, durability, and minimal maintenance requirements. Since it's easy and fast to apply, it lowers labor costs and inconveniences traffic. It also stays longer than traffic paint, saving costs on frequent replacement signage or repainting.

4. Conclusion

Thermoplastic paint is an economical, sustainable, and long-lasting option for road marking. Because of its high reflectivity, quick drying time, and adjustable options, it's also used in a wide range of applications. Construction companies can increase safety, lower maintenance costs, and lessen traffic interruption by choosing thermoplastic paint.

5. About EuroPlas - A reliable masterbatch manufacturer

EuroPlas is one of the leading manufacturers that can satisfy a wide range of requirements for unique plastic raw material solutions to optimize production costs and improve the competitiveness of the customers. We have a wide range of products to offer our cooperators:

Our product is a combination of calcium carbonate primary resin and other plastic additives based on the customers' requirements. It has many advantages, such as improved stiffness and bend strength, reduced shrinkage, the capability to enhance stability, printability, and surface quality of the final products, and energy savings. It helps manufacturers save costs, improve productivity and produce high-quality plastic products.

Our product is a combination of calcium carbonate primary resin and other plastic additives based on the customers' requirements. It has many advantages, such as improved stiffness and bend strength, reduced shrinkage, the capability to enhance stability, printability, and surface quality of the final products, and energy savings. It helps manufacturers save costs, improve productivity and produce high-quality plastic products.

Our color Masterbatch is made from high-quality pigments, carrier resin, and some special additives, creating a colorful and attractive appearance. Besides, it is not harmful to the environment and helps the manufacturers to save time and cost in the production process.

Our color Masterbatch is made from high-quality pigments, carrier resin, and some special additives, creating a colorful and attractive appearance. Besides, it is not harmful to the environment and helps the manufacturers to save time and cost in the production process.

EuroPlas has a wide range of additives for plastic, such as Flame retardants, Desiccants, Odor removing additives, Anti-UV additives, Anti-aging additives, Anti-fog additives, Antistatic additives, Anti-blocking additives, and Processing-aid additives. It can improve the material's performance according to specific requirements.

EuroPlas has a wide range of additives for plastic, such as Flame retardants, Desiccants, Odor removing additives, Anti-UV additives, Anti-aging additives, Anti-fog additives, Antistatic additives, Anti-blocking additives, and Processing-aid additives. It can improve the material's performance according to specific requirements.

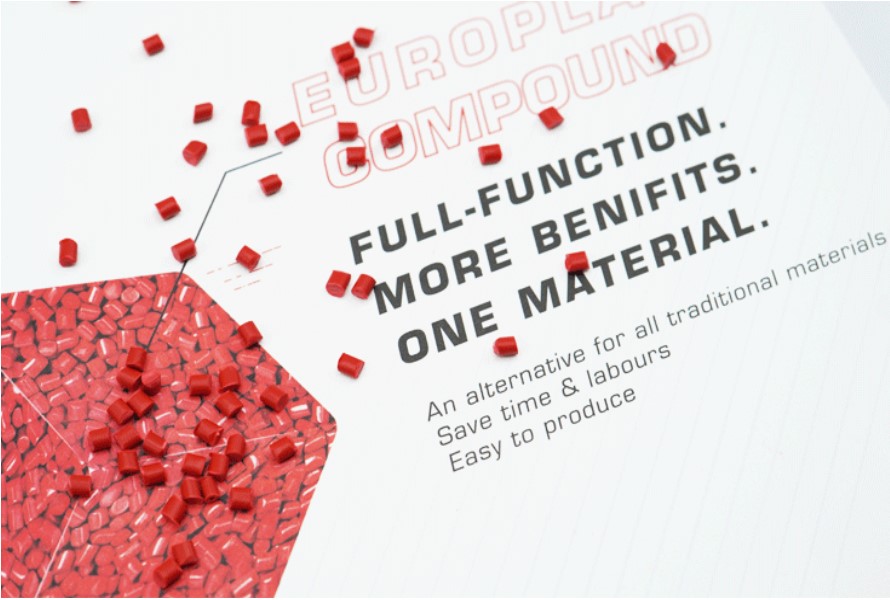

EuroPlas Engineering Plastic Compounds are various, including PA6, PA66 blend compound, PBT GF-FR compound, ABS Glass fiber compound, ABS Antistatic compound, PC flame retardant compound, and ABS. Their high-quality flexibility and other outstanding features are suitable for automobile, electronics manufacturing, interior decoration, and renewable energy.

EuroPlas Engineering Plastic Compounds are various, including PA6, PA66 blend compound, PBT GF-FR compound, ABS Glass fiber compound, ABS Antistatic compound, PC flame retardant compound, and ABS. Their high-quality flexibility and other outstanding features are suitable for automobile, electronics manufacturing, interior decoration, and renewable energy.

The Bioplastic Compound of EuroPlas is an innovative solution for sustainable industries and the environment. Our exclusive product, BioNext, can be decomposable within 12 months after use. The material will help your end product pass all strict quality control requirements.

The Bioplastic Compound of EuroPlas is an innovative solution for sustainable industries and the environment. Our exclusive product, BioNext, can be decomposable within 12 months after use. The material will help your end product pass all strict quality control requirements.

Contact us right now for more information!