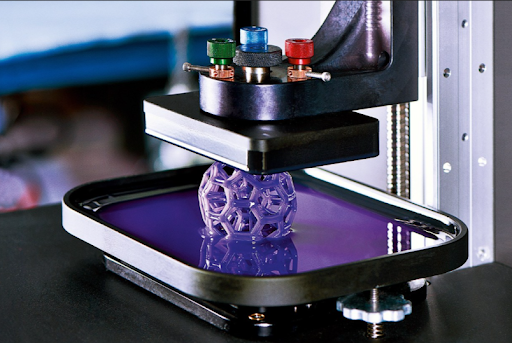

It can be seen that 3D printing with Nylon brings many products suitable for many different applications

3D printing with Nylon is currently favored by many fields thanks to its excellent properties for production and consumption. Known for its durability and multifunctional flexibility, Nylon is widely used in applications in many different industries. The following article is to help open up a more detailed perspective on the optimal material Nylon and its great benefits in the 3d printing with Nylon process. However, like any material, 3D printing with Nylon also comes with its own challenges and opportunities. Let's explore these useful aspects in detail below!

1. Understanding Nylon In 3D Printing

Nylon also possesses excellent flexibility, helping them easily return to their original shape after deformation

3D printing with Nylon is currently considered one of the most modern and advanced manufacturing methods. Printing in Nylon not only brings great benefits in product performance but is also flexible in the manufacturing process. In particular, Nylon is a flexible and multifunctional thermoplastic. It can be seen that 3D printing with Nylon brings many products suitable for many different applications. Thanks to the impressive properties of Nylon such as elasticity, durability, and good resistance to mechanical stress, 3D printing with Nylon products is ideal for harsh environments. Nylon also possesses excellent flexibility, helping them easily return to their original shape after deformation. This helps 3D printing with Nylon contribute to the diversity of device functions.

The 3D printing with Nylon process is suitable for a variety of different Nylon lines. Among them, Nylon 12 is preferred in printing in Nylon thanks to its low moisture absorption and excellent chemical resistance. They always perform well in positions that require durability. In addition, Nylon 6 in 3D printing with Nylon is known for its good tensile strength and high stiffness. The positions of Nylon 6 are often structural applications. In addition, some popular Nylon types in 3D printing with Nylon are Nylon 11, Nylon 66, Glass-filled Nylon, etc.

The advantages that 3D printing with Nylon brings to the manufacturing industry are extremely impressive. One of the main advantages of 3D printing with Nylon is its high strength-to-weight ratio. This helps the product to possess excellent durability but still have negligible weight. The products created in the 3D printing with Nylon process also have excellent flexibility. They allow the creation of equipment parts that can withstand repeated stress without breaking. In addition, Nylon also has excellent chemical resistance, low friction, high impact resistance making them always the ideal choice for many diverse applications.

Read more: What is nylon? All about its properties and common uses

2. Key Properties Of Nylon For 3D Printing

Printing products in Nylon can withstand exposure to a wide range of chemicals, oils and solvents without degrading

Flexibility: 3D printing with Nylon provides excellent flexibility to the application. This makes Printing in Nylon a great choice in the production of parts that require bending with the lowest fracture rate. Flexibility makes 3D printing with Nylon always highly appreciated in applications that are exposed to shock, vibration and frequent folding.

High strength-to-weight ratio: One of the most notable benefits of 3D printing with Nylon is its high strength-to-weight ratio. Nylon is one of the materials that meets a variety of mechanical factors, structural integrity while still ensuring light weight. This is one of the important factors to affirm the position of 3D printing with Nylon in many technical applications.

Chemical resistance: 3D printing with Nylon is always the recommended choice for applications that operate in harsh environments. Printing products in Nylon can withstand exposure to a wide range of chemicals, oils and solvents without degrading. This property ensures that the equipment maintains its integrity even in challenging industrial applications.

Low coefficient of friction: Parts manufactured from 3D printing with Nylon are always at the top of the list for the low coefficient of friction category. This property reduces wear and tear, prolongs the life of printed parts and ensures smooth operation.

Wear resistance: This property helps 3D printing with Nylon operate durably in environments where mechanical stress is repeated on the surface without much wear. Wear resistance is one of the factors that helps extend the life of equipment, limit maintenance and replacement.

3. Applications Of Nylon In 3D Printing

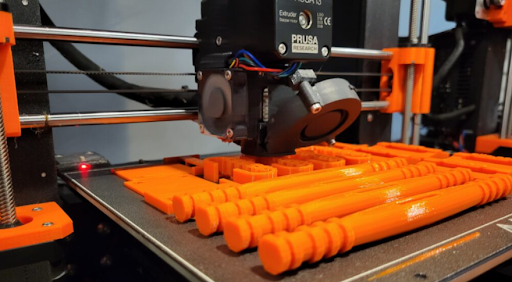

3D printing with nylon is one of the irreplaceable manufacturing processes in the constant development of human life today

3D printing with Nylon is known as a versatile manufacturing process for many applications in many different fields. Here are some areas in life that 3D printing with Nylon has contributed to:

Automotive parts: 3D printing with Nylon is present in many applications such as intake pipes, brackets, gaskets and connectors for car parts. The reason why Nylon can perform well in these positions is because Nylon possesses good chemical resistance, flexibility, and durability. In particular, despite bringing many great benefits, 3D printing with Nylon brings the ability to save fuel to the automotive industry thanks to its significant lightweight compared to other materials.

Aerospace components: Thanks to its durability and minimal weight, 3D printing with Nylon is always the ideal choice for the aerospace industry. Specifically, the high strength-to-weight ratio of Nylon helps them operate durably without taking up too much weight of the equipment. The weight of Nylon is extremely light, contributing to reducing the total weight of the aircraft and improving fuel efficiency. 3D printing with Nylon is suitable for complex designs, sophisticated assemblies such as pads between parts, gears, equipment joints, etc.

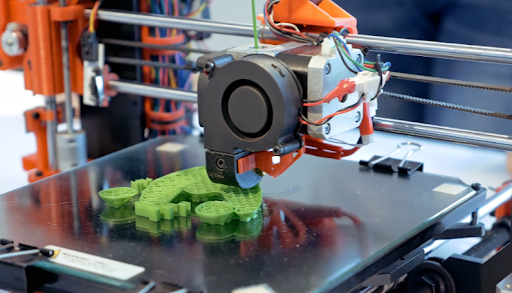

Consumer products: 3D printing with Nylon is currently one of the indispensable elements of the consumer goods manufacturing industry. Their common applications are easily encountered such as kitchen utensils, eating utensils, children's toys and some sports equipment. Nylon is a material that is safe for human health with many diverse designs and models. 3D printing with Nylon brings consumers beautiful and durable products over time.

Their common applications are easily encountered such as kitchen utensils, eating utensils, etc

Packaging industry: Some applications that 3D printing with Nylon contributes to this field include food packaging, electronic equipment packaging, agricultural packaging and some other packaging screens. Nylon with light weight, flexible helps protect the product extremely well without increasing the weight of the product. In particular, 3D printing with Nylon helps to give the product a fresh, diverse and eye-catching appearance from simple to sophisticated structures.

Medical equipment: 3D printing with Nylon brings enormous benefits to the medical industry. Nylon is a material that is safe for the skin, less bactericidal, and easy to shape. Some special applications that printing in Nylon has brought are prosthetic legs, artificial hands or some other orthopedic parts. In addition, equipment such as syringes, gloves, chemical containers, etc. are also easily encountered with Nylon. The durability of Nylon ensures that these devices still work over time while still being comfortable for the user.

4. Challenges Of 3D Printing With Nylon

Despite its numerous benefits, 3D printing with Nylon still needs to gradually improve its features in the face of the following challenges:

4.1. Moisture absorption

Low moisture absorption can affect the quality of 3D prints in a number of ways, such as poor surface finish, reduced durability, and warping during the printing in Nylon process.

The solution to this challenge in 3D printing with Nylon can be done by storing Nylon in a dry environment or in a sealed box with a desiccant. In addition, a dryer can be used before printing in Nylon to ensure optimal material performance.

4.2. Warping and shrinkage:

During the 3D printing with Nylon process, the product may encounter this phenomenon during the cooling step. This can lead to errors in the size of the finished product.

However, the solution to this challenge in the printing in Nylon process is not too complicated. Controlling the cooling process using a sealed press or heated chamber can reduce shrinkage.

5. Future Trends in Nylon 3D Printing

With the continuous development of today's industries, 3D printing with Nylon also has constantly changing trends. Here are some of the trends of printing in Nylon and their potential:

3D printing with Nylon always keeps up with the innovation trends to constantly develop and become more promising in creative 3D printing technology

5.1. Advanced Nylon blends:

As 3D printing technology develops, the development of advanced Nylon blends is also constantly evolving. In which, there will be more combinations of Nylon with polymers and necessary additives to enhance the desired properties of the material. This will bring about material blends with high value in terms of durability, heat resistance, low moisture absorption. These properties can be flexibly adjusted depending on the manufacturer's wishes.

Thanks to this, 3D printing with Nylon will have more potential benefits for both manufacturers and consumers. They can create equipment parts with more durable, stronger properties, and limited wear in harsh conditions. Overall, this amazing capability will open up new opportunities in industries such as aerospace, automotive, and medical devices.

5.2. Sustainable Nylon:

These days, environmental issues are being emphasized in every aspect of life. 3D printing with Nylon is also catching up with this trend. Promoting the development of sustainable Nylon fibers in printing in Nylon is an essential thing. These fibers are made from recycled or bio-based sources, helping to reduce the environmental impact of the manufacturing process.

This development for the 3D printing with Nylon industry is extremely potential. Sustainable Nylon fibers offer the dual advantage of maintaining the desirable properties of traditional Nylon while contributing to reducing carbon emissions. This is a very good signal for the broader movement towards green manufacturing.

6. Conclusion

In conclusion, 3D printing with Nylon is one of the irreplaceable manufacturing processes in the constant development of human life today. This is one of the materials that meets countless strict requirements such as durability, flexibility, multifunctionality, chemical resistance, abrasion resistance and light weight. Thanks to these outstanding features, they have become one of the important factors in various fields such as automotive technology, aerospace, medical devices, packaging technology, etc. 3D printing with Nylon is a great innovation in the additive manufacturing industry. Not stopping there, 3D printing with Nylon always keeps up with the innovation trends to constantly develop and become more promising in creative 3D printing technology.

3D printing with Nylon is a great innovation in the additive manufacturing industry

7. About EuroPlas’ Polyamide Products

EuroPlas is a renowned leading manufacturer of premium filler masterbatches, bioplastics, plastic additives, engineering plastic compounds, etc. Among the company's highly regarded products are Polyamide 6 (PA6) and Polyamide 66 (PA66) compounds, important materials widely used in various industries.

PA6, PA66 blend compound is a blend of PA6, PA66 resin and elastomer. The most common application of PA6, PA66 blend is in the automotive and motorcycle industry. This material is commonly used in roller bearings, office equipment, carburetors, exhaust control valves, fuel tank products and other gear-related components.

PA6, PA66 blend compound is a blend of PA6, PA66 resin and elastomer

PA66, PA6 Glass fiber compound is a composite of PA resin and reinforced glass fiber. It has excellent toughness, wear resistance, chemical resistance, temperature variations such as high heat and strong mechanics. In addition, this material is stable, electrically insulating and easy to mold.

EuroPlas' PA6 and PA66 compounds are indispensable choices in industries ranging from automotive and electronics to industrial manufacturing. Highly regarded for their mechanical properties, heat resistance and chemical resilience, these engineering plastic compounds serve as indispensable components in high-performance engine components, electrical connectors and gear systems.

Visit EuroPlas' extremely useful blog today! Where you can learn more about the engineering plastic compound solutions that are suitable for your upcoming project!

Read more: PA6, PA66 blend compound

Read more: PA66, PA6 Glass fiber compound