Plastic is quite popular nowadays as a material to create products not only for daily life but also for modern industrial production. But have you ever had trouble finding the right material or wondered which one is the strongest plastic? This article will give you detailed information and answer your questions.

1. The Contenders: The Strongest Plastics

In today's world, various types of plastics can be used in different industries. Here are the top three strongest plastics based on their heat resistance, durability, and application versatility.

1.1. Polypropylene - PP

Polypropylene - PP

Polypropylene, also called PP, is a type of thermoplastic polymer formed from the combination of propylene monomers. It can be utilized in most aspects of life, such as making plastic components in the textile and automotive industries and packaging consumer products. There are seven types of PP plastics: copolymer, homopolymer, impact copolymer, expanded polypropylene, terpolymer, polypropylene with high melt strength, and biobased polypropylene but the one we commonly see in various industries is homopolymer.

PP plastic sheets are very hard, which is often compared to steel in the plastic industry due to their unique manufacturing process and added additives. Smooth surfaces make PP plastic sheets a suitable replacement to other plastic materials commonly used for interior liners and gears. Additionally, the smooth surface prevents PP plastic sheets from adhering to other surfaces easily, which is both an advantage and a disadvantage, as welding may be required to bond them together when needed.

1.2. Teflon - PTFE

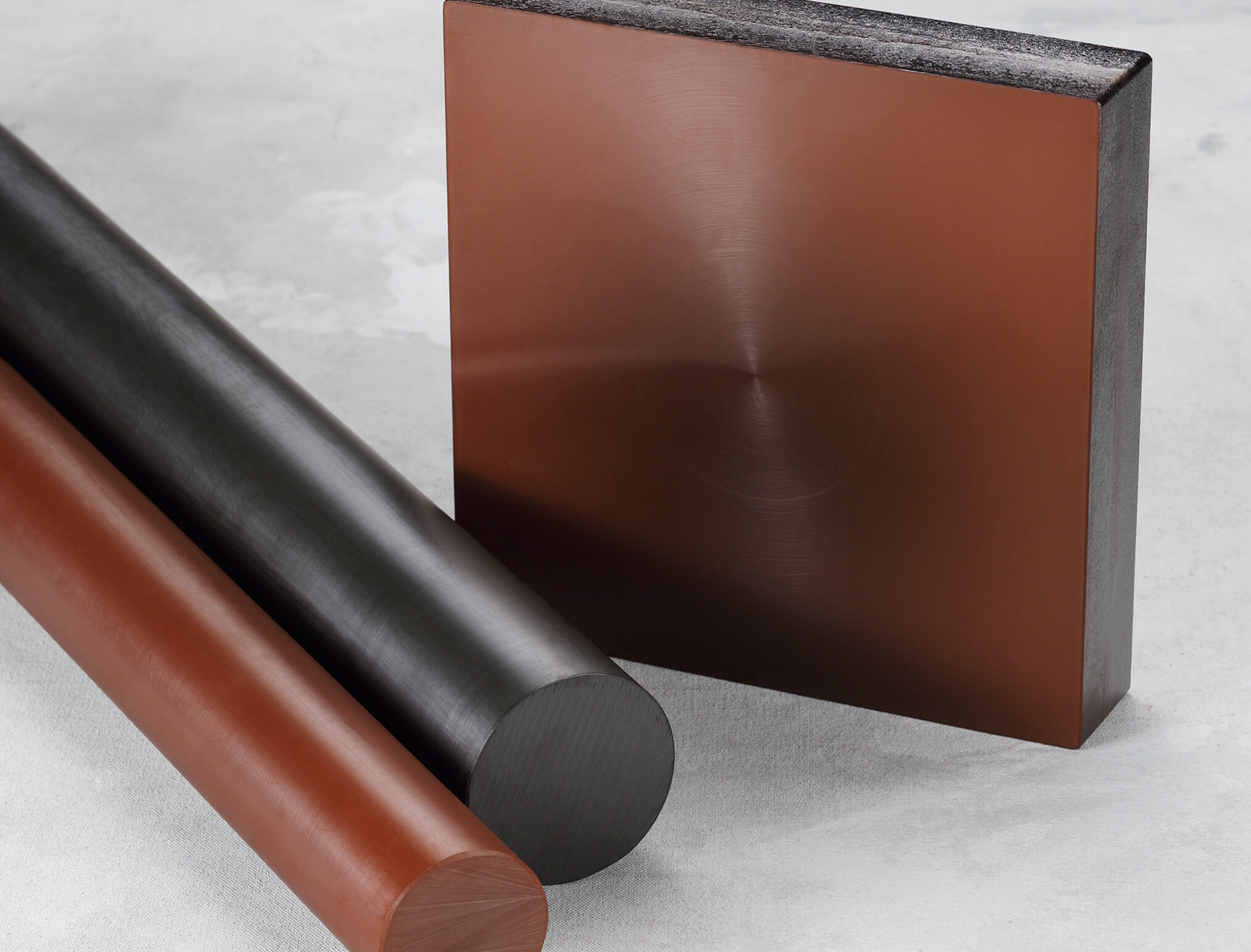

Teflon - PTFE

Teflon, also known as PTFE (Polytetrafluoroethylene), is a synthetic fluoropolymer compound that possesses excellent chemical resistance and high melting temperature. Products made from PTFE sheets can withstand both high and low temperatures, corrosion, and chemical reactions.

Additionally, Teflon's low friction and electrical properties have made it a primary material in the manufacturing industry. PTFE sheets are one of the most heat-resistant plastic materials that can maintain stability at temperatures up to 260 degrees without significant decomposition. Therefore, it is recently considered to be one of the strongest plastics.

1.3. Vespel

Vespel heat-resistant plastic

Vespel is one of the strongest plastics that can withstand high temperatures of 288 degrees, and even reach up to 482 degrees for a limited time without any changes to its mechanical or thermal properties.

This makes Vespel a popular choice for many applications, such as automotive, jet engines, trucks, and various industrial machinery. Moreover, this type of plastic has high strength, flexibility, good impact resistance, low friction, and the ability to resist chemical corrosion.

2. Choosing the Strongest Plastic: It Depends

Determining the strongest plastic is a difficult task as it primarily depends on its specific use in different applications. Each type of plastic possesses its unique properties, which make it suitable for various requirements and usage conditions.

For instance, in medical applications, safety, and high durability are essential factors, making plastics like polycarbonate (PC) or polypropylene (PP) the preferred choices.

On the other hand, the automotive industry requires plastics that offer heat resistance and mechanical strength, making plastics like acrylonitrile butadiene styrene (ABS) or polyamide (PA) irreplaceable options. Therefore, determining the "strongest plastic" not only depends on its physical properties but also on its use and specific requirements for applications in life.

The table of comparison of the strongest plastic

| Type of plastics |

Teflon |

Vespel |

Polypropylene |

| Properties |

- Good abrasion resistance

- Non-flammable, oxygen limit index is below 90

- Low friction coefficient (0.04)

- Teflon plastic does not become brittle in gaseous air, does not soften in boiling water, and does not change state at temperatures ranging from -200°C to 260°C.

- High dielectric properties

- Resistant to aging in atmospheric conditions, good gas barrier properties

|

- One of the best synthetic materials with a high organic molecule content.

- Withstanding temperatures above 400°C regular operating temperature -200 to 300°C.

- Superior mechanical properties

|

- Transparent and colorless

- High-gloss surface, making it easy to print

- PP plastic is not as flexible as PE plastic

- Withstanding high temperatures up to 100°C, melting at 165°C

- PP plastic is not oxidized and has gas barrier properties

|

| Applications |

- Used as a liner for hoppers, containers, chutes, and gravity conveyors to reduce blockages and improve sliding ability.

- Employed to produce machine components like bearings and bushings.

|

Aerospace technology, semiconductors, and transportation |

- Producing packages for unprocessed food and agricultural products.

- Industrial applications such as liquid storage tanks, industrial cutting boards, and footwear.

|

| Technical specifications |

-Density: 2.1 - 2.3 g/cm³

-Hardness: 55 - 65 Shore A

-Tensile strength: 15 - 35 MPa

-Elongation: 150 - 350%

-Melting temperature: 327°C

|

- Melting temperature: 500–600 °C |

-Tensile strength: 30 - 40 N/mm²

-Elongation: 250 - 700%

-Melting temperature: 165°C

|

3. Conclusion

In conclusion, it is quite challenging to determine which plastic is the strongest because each type of plastic has different properties that can be used in various fields. Therefore, it is not necessary to choose the strongest plastic, users should select the type that suits their needs.

4. About EuroPlas

EuroPlas is the world's largest filler masterbatch manufacturer. We offer a wide range of plastic products that cater to diverse business needs globally. Our product offerings include bioplastic compounds, color masterbatch, plastic additives, engineering plastic compounds, filler masterbatch, and bio-fillers. In addition, EuroPlas also offers PP products such as PP filler masterbatch and various PP engineering plastics: flame-retardant compound, conductive compound, BaSO4 compound, talc compound, glass bead compound, and fiberglass compound.

Remember to take some time to explore our blog, which features a wealth of information about plastics and current business trends in the plastic industry.