Plastic can produce high-quality boxes

The application of plastic materials in the goods transportation, import and export industries or even the food industry is a significant step forward in the development of human production activities. The process of producing high-quality plastic containers requires us to clearly understand the properties of plastic materials, the properties of the product being targeted and some notes on production methods. Right in this article, please join us in updating essential information about high-quality plastic boxes!

1. What is a plastic box?

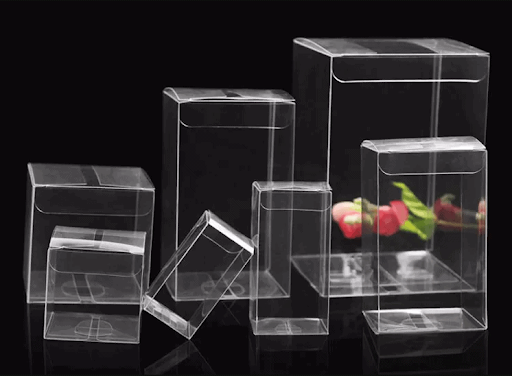

Plastic boxes in many different sizes and colors

Plastic containers or plastic packaging in general are produced with the main ingredient being plastic (various types of plastic). Plastic is a material produced from natural gas and crude oil. Through processing and advanced chemical methods, people transform crude oil into a variety of different types of plastic depending on their needs. This plastic material will be designed and shaped through a number of technical methods to create products for consumers, including plastic boxes. According to the development of today's life, plastic products in general and plastic containers in particular have become an indispensable part.

We can easily see plastic boxes in many different shapes and colors everywhere. Industries with very high demand for the production of plastic containers or plastic packaging include the food and beverage industry, cosmetics, medical products, agricultural packaging, household consumer goods, chemical and pharmaceutical industries. , etc. The main demand is to produce food and drink packaging, food trays (cans, water bottles, soft drinks, cake boxes, etc.), product protective packaging, medicine bottles, pesticide bottles and many other chemical containers (shampoo, detergent).

2. Top materials for producing high-quality plastic boxes

HDPE is the safest plastics because of its antibacterial properties

HDPE is also known by its full name High-density Polyethylene. In terms of structure, HDPE is created from the process of collecting ethane from the heating of ethylene gas. Once obtained, this gas compound is mixed with benzene and exposed directly to UV radiation. HDPE has a high strength-to-density ratio, so it is famous for its excellent durability. This is a thermoplastic with a melting index of up to 160°F. In terms of properties, HDPE possesses excellent properties such as super durability, hardness, impact resistance, antibacterial and good chemical resistance. Bottles made from HDPE can resist organic solvents such as salts, bases, acids and some other corrosive chemicals. Besides, HDPE is also known as one of the safest plastics because of its antibacterial properties that are safe for human health, and its ability to be recycled is extremely environmentally friendly. Products made from HDPE plastic include big plastic containers, shampoo bottles, cosmetic bottles, pesticide bottles, detergent bottles, and a variety of food packaging bottles

Read more: HDPE (High density polyethylene) - What is it? Properties & common uses

LDPE containers are flexible and squeezable

If HDPE plastic is an optimal choice for rigid containers, LDPE is a great choice for containers with a flexible design. Regarding structure, the polymer chains of LDPE are linked by weak molecules so the hardness will be lower than that of HDPE. Because of this characteristic, LDPE plastic is very suitable for producing bottles or packaging that are flexible and squeezable. The variety of manufacturing applications is similar to HDPE including the food, agriculture, pharmaceutical and healthcare industries, etc.

Read more: What is LDPE (Low density polyethylene)? Properties & applications

PET is very safe for human health

PET plastic's full name is polyethylene terephthalate. This is a line of transparent thermoplastics that is very commonly used in product packaging design in a variety of industries. Regarding structure, to obtain PET plastic, ethylene glycol and terephthalic acid will be combined together to form polymer chains that are then cut into small plastic particles. In terms of properties, PET is a plastic line that has been recognized by the FDA as very safe for human health thanks to not containing phthalate and BPA. In terms of mechanics, PET possesses extremely impressive parameters of resistance to damage, antibacterial, high durability and good flexibility. This is one of the types of plastic that can be recycled but requires thorough cleaning before reuse. Typical products made from PET include packaging in direct contact with food and drinking water, food storage containers, chemical bottles and product protective films.

Read more: What is Polyethylene terephthalate (PET)?

PP plastic for food storage box applications

PP plastic is known by its full name Polypropylene (C3H6). In terms of structure, PE is a non-polar polymer with a bond density of about 0.855 grams per cubic centimeter. The melting point of PP plastic ranges from 130 degrees Celsius to 171 degrees Celsius. During the production process, PP plastic has the ability to combine excellent colors thanks to its transparent, colorless, and odorless properties. In terms of properties, PP plastic has good elasticity, electrical insulation, high temperature resistance and deformation resistance. Besides, PP is also a type of plastic that is not harmful to human health, so it is used in the production of food packaging, food containers, water bottles, 20 liter water bottles, etc. Thanks to its transparency, consumers love PP plastic for food storage box applications.

Read more: PP Plastic: Everything you need to know

PVC plastic containers

PVC plastic's full name is Polyvinyl Chloride (CH2=CHCl or C2H3Cl). For PVC, this substance can be combined with plastic stabilizers, impact modifiers or some plasticizers to produce products. In terms of properties, PVC plastic has ideal heat resistance with a melting point that can reach 260 degrees Celsius. This is one of the materials that attracts many investors thanks to its relatively reasonable price and high durability. and good electrical insulation. In the field of plastic containers and product packaging, PVC is used to produce large drums, shipping containers, and a variety of containers in chemical production and containers in water supply systems.

Read more: What is PVC Plastic? All Information About PVC Plastic

PS plastic in applications food and beverage packaging

PS plastic is known as Polystyrene ((C8H8)n). This is one of the materials produced with high frequency in food container applications. The melting point of PS is quite high, up to 240 degrees Celsius. In terms of properties, PS plastic can be made in many forms such as hard, flexible, and porous but is easily oxidized. PS plastic has good waterproofing properties so it is used for containers that have direct contact with water. This type of plastic is not recommended for recycling, so PS plays a key role in the production of single-use plastic packaging and boxes. We can easily encounter PS plastic in applications such as takeout food boxes, disposable plastic cups, food and beverage packaging.

Read more: Everything you need to know about polystyrene

2.7 Polycarbonate (PC)

This plastic is known for its good water resistance

PC plastic is also known as Polycarbonate. This plastic line is known for its durability, good water resistance, high temperature resistance and outstanding fire resistance. Applications of PC plastic in the packaging industry include food boxes and beverage bottles

2.8 Acrylonitrile Butadiene Styrene (ABS)

ABS in the production of battery boxes

ABS plastic is known as Acrylonitrile Butadiene Styrene. This is also one of the materials that can be considered in the production of plastic boxes. ABS stands out with its toughness, good hardness and resistance to acids and alkalis. Unlike the plastic lines mentioned above, ABS is one of the top choices in the production of battery boxes.

Read more: Comparing ABS vs PE Plastics | Which is Better for Processing?

3. Popular high-quality plastic containers

Plastic folding box

We can easily encounter plastic folding boxes in the process of transporting goods. This is one of the most popular plastic containers specifically used for transporting food such as eggs, vegetables, fish, fruit, etc. The design of the plastic folding box provides flexibility, elasticity, breathability, and good impact resistance, thereby helping to protect food from damage during transportation. Besides, thanks to its lightweight, plastic folding boxes help save significantly on fuel compared to the consumption of transportation machinery and equipment.

Plastic storage box

Plastic boxes are designed to preserve personal tools, store food in the refrigerator or store other foods or objects. The advantage of this type of production is to provide consumers with containers with a variety of colors, shapes and sizes.

Plastic container for transportation

- Plastic container for transportation

Containers made of plastic often prefer hard plastic materials such as HDPE or PVC. The requirement for these plastic materials is to maintain the durability of the container even when exposed to chemicals or acids. In industries such as chemical transportation, wastewater treatment, medical waste treatment, water storage tanks, etc.

Plastic bottles

- Plastic cans or plastic bottles

Plastic materials such as PS, PP, PET, etc. can be used to make plastic cans or plastic bottles. Plastic bottles can be easily found such as 20 liter water barrels, soft drink cans, mineral water bottles, and some plastic bottles containing cosmetics.

4. Why should we choose plastic boxes?

Plastic boxes can be recycled

- Low cost (material fee and production fee)

Plastic boxes are becoming more and more popular and gradually replacing materials such as wooden boxes or metal boxes. With increasing consumer demand, optimizing material and production costs is one of the top priorities. Plastic materials meet a moderate price, the production process is not too complicated and does not require a team of experts.

Plastic plays a key role in the packaging and packaging industry because of its rapid and diverse forming process. Plastic is a material that can be suitable for manufacturing techniques such as molding, 3D printing, injection molding, extrusion, etc. Moreover, plastic and plastic materials can produce a series of high-quality containers and packaging with many unique shapes, creative designs and diverse sizes.

Plastic is a material that can design extremely durable containers and product covers. The main reason for this characteristic is because plastic is one of the compounds with very good hardness (some types can be harder than metal). Conf durability is expressed through other characteristics such as flexibility, toughness, good impact resistance, tear resistance, good heat resistance, chemical resistance and some corrosive acids. Containers made from plastic materials will provide users with a durable product over many years.

Plastic boxes are many times lighter in weight than metal boxes or wooden, glass or ceramic boxes. Containers made of plastic are often thinner and lighter but still ensure excellent durability over weight. For container applications used to transport goods, minimizing the volume of the container will help the transportation process save significant fuel.

Environmental friendliness is one of the top requirements in the packaging industry. The number of product containers and packaging boxes is increasing, so taking advantage of recyclable plastic will help largely reduce the amount of waste released into the environment

5. Conclusion

In general, it can be said that plastic boxes are an ideal choice that both saves costs (for both manufacturers and consumers) and meets a variety of needs in life. Choosing the right material for high-quality plastic containers or plastic packaging boxes depends on the type of product the manufacturer is aiming for. Read more useful articles from EuroPlas to make the right choice for your upcoming projects!