Nylon plastic sheet is one of the common materials in production industries. Thanks to its strength, stiffness, and outstanding bearing and wear properties, Nylon is an alternative to many metal bushing and bearings, thus reducing the requirement for external lubrication. Moreover, the material can lighten the part weight, produce less noise while operating, and give the mating details better wear resistance. Let's follow along to see where nylon plastic sheets are mostly applied right now!

1. What is a nylon plastic sheet?

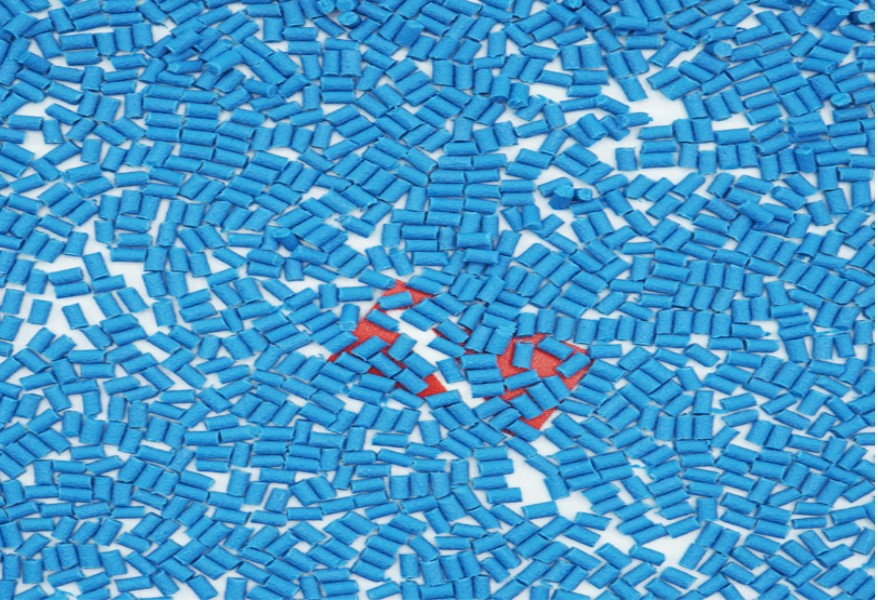

Nylon plastic sheets are synthetic thermoplastic linear polyamides used in many industries, especially engineering applications, including seals, gears, etc. The sheets of Nylon are usually available in natural white and black.

In general, there are 2 grades of Nylon: extruded and cast grades. The cast ones are tougher and easy to process. It can be made into a thick profile with a thickness of more than the standard 100mm. Besides, the nylon plastic sheets can also come in metal-detectable, oil-filled, and flame-retardant versions.

Read more: What is Nylon? All about its properties and common uses

2. Why should you use nylon plastic sheets?

Nylon is well-known for its toughness and strength. It provides a great balance between sudden impact and long-term wear resistance (while other materials can only satisfy one of these two requirements). Therefore, Nylon is considered a major asset in many industries.

The material is lightweight and easy to handle. It's much easier to machine than other materials and metals that it usually replaces.

Nylon has great versatility, allowing it to be cut in different sizes, shapes, and thicknesses to meet the requirements of specific final products or components. Therefore, you'll see nylon providers usually offer flat nylon sheets in various dimensions to fit different applications. In addition, the material features both extruded and cast versions. Extruded type or type 6/6 nylon provides a great balance of various properties, such as low coefficient of friction and excellent impact and heat resistance. Thus, it's an ideal alternative to metal. Meanwhile, the cast version, also known as type 6 nylon, is suitable for complex machined parts and near-net shapes since it comes with good dimensional stability and machinability. Furthermore, according to the specific needs of final products, the nylon plastic sheet can also be produced with added attributes such as FDA-compliant, glass-filled, oil-filled, MoS2-filled, etc.

3. Most common applications of nylon plastic sheets

3.1. Machine parts

Thanks to its lightweight nature, durability, and heat and chemical resistance, Nylon can be used as plastic in producing machine parts, including bolts, nuts, and screws. Since the material provides a low coefficient of friction and excellent abrasion resistance, it's used to make bearings or sliding and rotating parts in the mechanisms. Moreover, Nylon is also present in electronic items such as electrical cords and circuit boards.

3.2. Construction applications

Since Nylon can be molded into various films and sheets, it has a wide range of applications in the construction field. Custom-cast nylon is the ideal material for industrial hammerheads, crane pads, etc.

Nylon is easy to melt into sheet stock for CNC machine manufacturing or filaments for 3D printing. Besides, it also works well with injection molding.

4. EuroPlas - Where to find the best PA (nylon) engineering plastic compound

If you choose Nylon for your final products, getting the material from trusted brands is important. As one of the leaders in the masterbatch fields, EuroPlas has produced and supplied PA (Nylon) Engineering Plastic Compounds and other engineering materials to over 90 countries in the world. We've got thousands of positive feedback about our products. They are the optimal solution with high quality and flexibility. With our all-functions-in-one materials, you can save time and effort and dramatically increase productivity.

Here are our highlighted PA (Nylon) Engineering Plastic Compounds

It's a combination of PA6, PA66 resin and elastomer. PA6 and PA66 are two typical types of Nylon that have their own advantages. The former is cheaper, easy to process, and deforms less, while the latter provides better stiffness and abrasion resistance and higher temperature resistance. Combining these two types can eliminate their disadvantages (low melting temperature of PA6 and low water absorption of PA66) and enhance the final product's quality. The mixture is resilient with strong mechanical properties, making it suitable for the automobile and motorcycle industries. Some common applications of the material are office equipment, roller bearings, carburetors, control valves, fuel tank lids, exhaust gas, and other gear-related parts.

The compound is made of PA resin and reinforced with glass beads or glass fibers (30-50%). It has great toughness, wear resistance, chemical resistance, high heat deflection temperature, and mechanical strength. Besides, the material is stable, electrically insulated, and easy to mold. That's why it is widely used in producing gears, bearings, drive belts, carburetor components, computer components, or household electrical components.

If you want to know more about PA (Nylon) Engineering Plastic Compound and other engineering materials, EuroPlas is always happy to help. Contact us for more detail right now!