Understanding the concept of a semi crystalline polymer is essential for grasping its unique properties and applications in various industries. This distinctive combination imparts a range of desirable characteristics, including enhanced strength, thermal stability, and flexibility. In this article, we will delve into what defines a semi crystalline polymer, how its structure affects its performance, and the benefits it offers in applications such as packaging, automotive parts, and medical devices. Whether you're a student, engineer, or industry professional, understanding semi crystalline polymers will provide valuable insights into their role in modern materials science.

Read more:

1. What Is A Semi Crystalline Polymer?

A semi crystalline polymer is a type of polymer that exhibits both crystalline (ordered) and amorphous (disordered) regions within its molecular structure, resulting in a unique combination of properties that are highly valued across various industries. The crystalline regions in a semi crystalline polymer contribute to its rigidity, strength, and high melting point, making these materials particularly resistant to heat and wear. This structural order also enhances the polymer's mechanical performance, allowing it to withstand significant stress and strain without deforming.

On the other hand, the amorphous regions provide the material with a degree of flexibility and impact resistance, ensuring that it remains tough and durable under various conditions. Due to this balanced profile, semi crystalline polymers are widely used in demanding applications, such as in the automotive industry for manufacturing engine components, in the packaging sector for creating durable films, and in medical devices where both strength and flexibility are critical. The versatility and resilience of semi crystalline polymers make them an essential material in modern manufacturing, where performance and reliability are paramount.

2. How Many Plastics Are Semi Crystalline Polymers?

A variety of commonly used plastics fall under the category of semi crystalline polymers, each offering a unique set of properties that make them suitable for different applications. Here are some key examples:

- Polyethylene (PE): One of the most widely used plastics, polyethylene is a semi crystalline polymer that comes in various densities, including low-density (LDPE) and high-density (HDPE). Its semi crystalline structure provides excellent impact resistance, flexibility, and durability, making it ideal for applications such as packaging, plastic bags, and containers.

Read more: PE plastic - Everything you need to know

- Polypropylene (PP): Polypropylene is another prominent semi crystalline polymer known for its strength, chemical resistance, and high melting point. It is commonly used in automotive parts, household goods, and food containers. Its semi crystalline nature gives it a balance of rigidity and toughness, suitable for demanding applications.

- Polyamide (Nylon): Nylon, or polyamide, is a semi crystalline polymer renowned for its high strength, abrasion resistance, and thermal stability. It is widely used in textiles, engineering components, and various industrial applications. The crystalline regions in nylon enhance its mechanical properties, while the amorphous regions contribute to its flexibility.

These semi crystalline polymers are integral to a multitude of industries, providing essential properties like durability, heat resistance, and mechanical strength. Their versatility and performance make them key materials in modern manufacturing and everyday products.

3. How To Increase Crystallinity Of A Polymer?

Increasing the crystallinity of a semi crystalline polymer enhances its mechanical properties and thermal stability. Here’s a detailed look at various methods to achieve higher crystallinity:

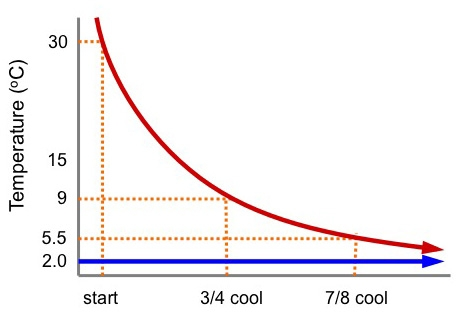

- Controlling the Cooling Rate: One of the most straightforward methods to increase crystallinity is to control the cooling rate during polymer processing. Slow cooling allows polymer chains more time to align and form crystalline regions, resulting in a higher degree of crystallinity. Rapid cooling, on the other hand, can trap the polymer chains in an amorphous state, reducing crystallinity. By optimizing the cooling rate, manufacturers can improve the strength and rigidity of the semi crystalline polymer.

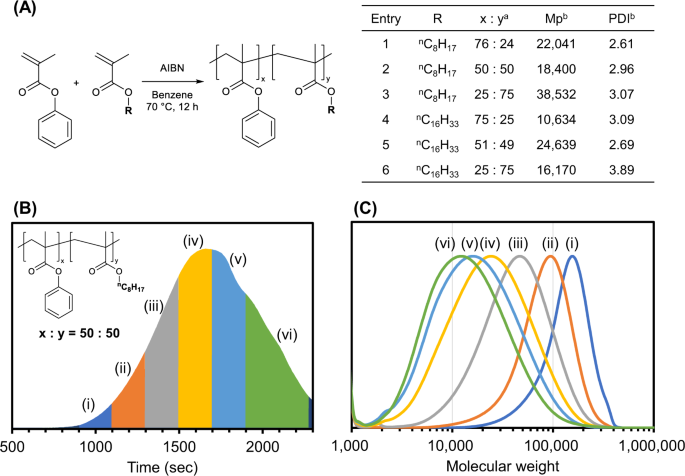

- Optimizing Molecular Weight: The molecular weight of a polymer influences its crystallinity. Polymers with higher molecular weights tend to form more crystalline structures because longer polymer chains can align more effectively. Adjusting the polymerization process to produce higher molecular weight polymers can enhance crystallinity, leading to improved mechanical properties and thermal resistance.

- Using Nucleating Agents: Nucleating agents are additives that promote the formation of crystalline regions within the polymer matrix. These agents create additional sites where crystallization can begin, facilitating the growth of crystalline structures. Incorporating nucleating agents into the polymer formulation can significantly increase the degree of crystallinity, improving the polymer's strength and thermal stability.

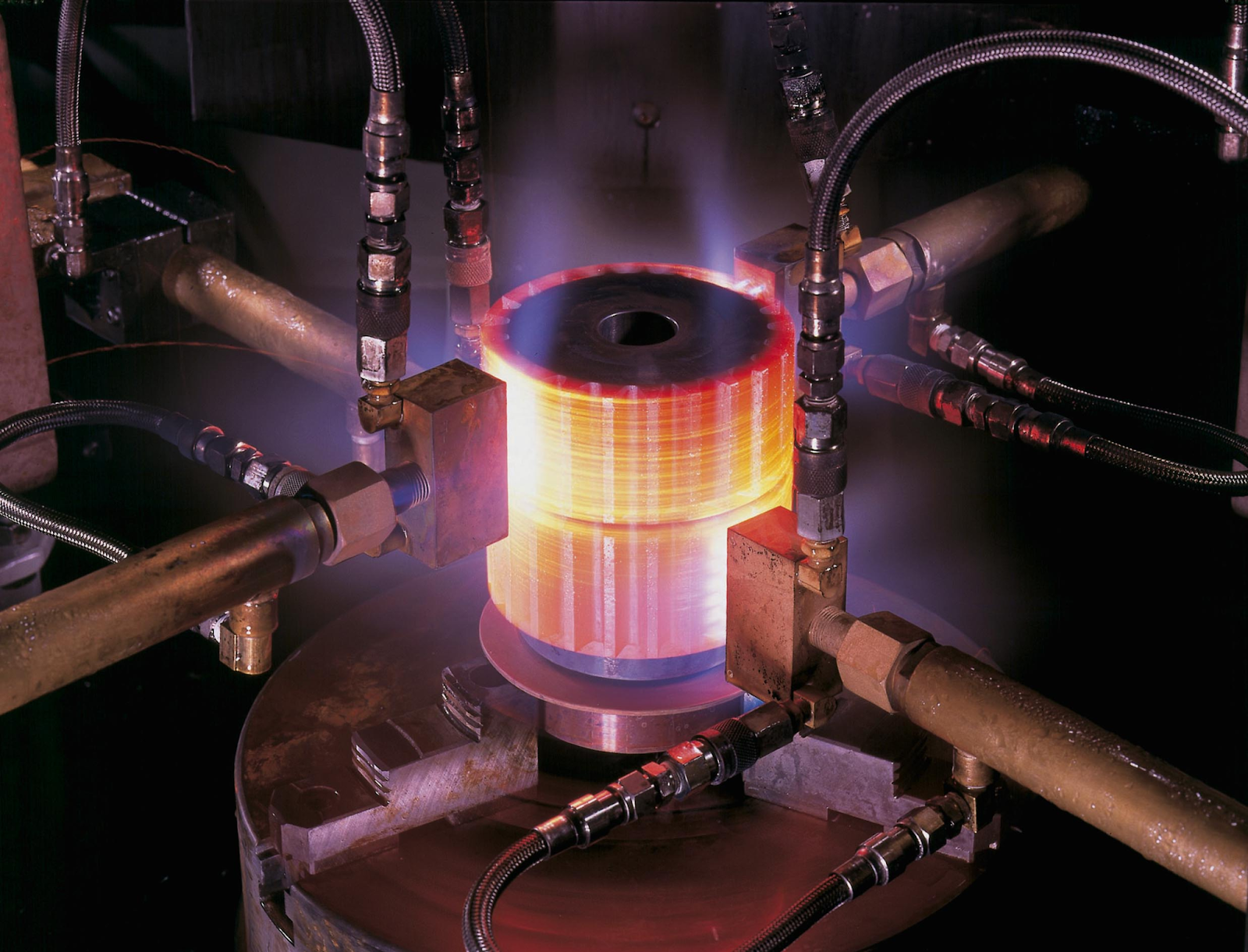

- Annealing: Annealing involves heating the polymer to just below its melting point and then cooling it slowly. This process allows the polymer chains to rearrange and form more crystalline structures. Annealing can be particularly effective in enhancing the crystallinity of semi crystalline polymers by providing a controlled environment for the polymer chains to align and crystallize.

- Adjusting Processing Conditions: The processing conditions, such as temperature and pressure, play a crucial role in determining the crystallinity of a polymer. By optimizing these conditions during polymer processing, manufacturers can influence the polymer's crystallization behavior. For instance, higher processing temperatures can promote crystallization, while specific pressure conditions can also affect the formation of crystalline regions.

Each of these methods can be used individually or in combination to increase the crystallinity of semi crystalline polymers, enhancing their performance characteristics for various applications.

4. Conclusion

In summary, a semi crystalline polymer is defined by its unique combination of crystalline and amorphous regions, which imparts a range of beneficial properties. Understanding these polymers’ characteristics helps in selecting the right materials for specific needs and optimizing product performance. As technology advances, the role of semi crystalline polymers continues to be pivotal in developing high-quality, durable, and efficient materials.

5. About EuroPlas

As a reliable partner to numerous clients, EuroPlas offers extensive solutions and support, from material selection to customization and production. With a dedication to continuous customer satisfaction, EuroPlas has demonstrated its outstanding capability in delivering for organizations working on high-performance material projects.

For further details about our services, including innovative solutions for your project, visit our website at EuroPlas. Don’t forget to check out our blog, which contains a wealth of information on different plastic materials and production development solutions.