Nylon vs. PLA: What Are The Differences?

Nylon vs PLA have both contributed greatly to the creation of today’s contemporary industries. While Nylon stands out for its durability and strength in demanding applications, PLA is highly regarded for its eco-friendliness and biodegradability. In particular, Nylon vs PLA offers unique cost benefits when properly explored and exploited. The choice of material will be the step that makes a dramatic difference in the performance and sustainability of your product. The following article will provide the most detailed perspective and Nylon vs PLA to help you find the perfect answer for your upcoming project!

1. Overview of Nylon and PLA

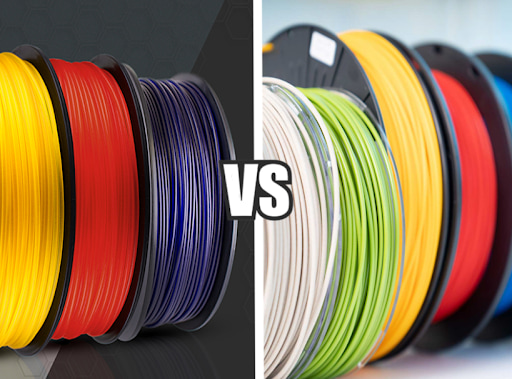

Nylon vs PLA offers unique cost benefits when properly explored and exploited

When comparing Nylon vs PLA, It can be based on a few basic details. Nylon is a synthetic polymer built from polyamide chains usually made from petrochemicals. It is prized for a remarkable strength to weight ratio and resistance to abrasion that earns it the title of favorite material used in sectors such automotive, aerospace and textiles. Wherever (car parts, industrial machinery or high performance apparel) Nylon goes it grabs attention because of its durability and tolerance for heat & chemicals. It is so high in demand right now due to manufacturers looking for more lightweight, hard wearing materials to enhance the efficiency and performance in advanced manufacturing. Therefore, Nylon is considered as the tip material of most high-tech industries due to versatility and dependability.

Read more: What is Nylon? All about its properties and common uses

Conversely PLA (polylactic acid) which is a biodegradable polymer derived from renewable materials, such as corn starch or sugarcane. PLA is critical for the move to a manufacturing based on more natural, sustainable materials. It is of light weight, strong and easy to mould, which is how it finds mass popularity for packaging, 3D printing and disposable items. More and more people, both consumer and production are aiming to consume biodegradable plastics in all of life applications so that PLA is being demanded like essential material. It is now an important stakeholder in eco-friendly markets, particularly in packaging and single-use applications. Because PLA is derived from a renewable source and has the ability to be composted, it is a way for companies to achieve sustainability while attracting environmentally-minded buyers.

Read more: How Is PLA Plastic Made?

2. Comparing Properties of Nylon vs. PLA

When choosing between Nylon vs PLA, understanding their key properties is essential to determine which material best suits specific applications. These comparison below highlights their strengths and differences across crucial attributes:

2.1. Strength and Durability

It refers to the ability that material does not fail under stress or wear over time. In this, Nylon is known for its superior strength and durability. This material can keep the shape with hardly any warp against pressure or environmental impact. PLA at least is fairly stiff (more brittle) but will crack from stress. That is why Nylon is more suitable for applications that demand strength and durability, such as mechanical elements and industrial parts.

2.2. Thermal Resistance

It will demonstrate how well a material resists temperature decay, in other words performance/temperature. Nylon is a very good heat resistant material, stable even over 100°C. On the other hand, PLA will be melted at temperatures above 60°C and bends sometimes.When Nylon vs PLA are in instances of heat exposure (car parts or machining), Nylon is clearly the superior material.

PLA comes from plants and is biodegradable, so this is a pretty natural choice for a lower impact on the environment

2.3. Eco-Friendliness

This property is very vital when talking about Nylon vs PLA which shows the sustainability and environment friendly background made by material. PLA comes from plants and is biodegradable, so this is a pretty natural choice for a lower impact on the environment compared to materials from fossil fuels. Nylon (synthetic, polymer derived from petrochemicals) is not biodegradable and cannot be recycled, less sustainable. It can be found that PLA is better for industries that are conscious of the eco, especially in the packing and disposable product industries.

2.4. Flexibility and Processability

As the name implies, flexibility and processability is how Nylon vs PLA can be molded, how adaptable they are to different designs. Examples of this flexibility, Nylon is very malleable which makes it possible to generate complex, durable designs. However Nylon is very specialized and needs advanced manufacturing equipment. On the other hand, PLA which is easier to work with because it can be melted at high heat. One important thing is that PLA is also hard to malleable because of its brittle. Therefore, Nylon vs PLA both have their own notes when processing to make sure the quality of products and effectiveness of the production.

2.5. Moisture Absorption

In this part, it will show how much Nylon vs PLA can soak up moisture, which is related to properties and life of objects. Nylon has a tendency to take in moisture from the air, which little by little reduces its strength and dimensional stability. Moisture absorption in PLA is very low and it is very stable in the humid environment, contrarily Nylon. And of course PLA proves to be more moisture resistant making it an unbeaten where moisture resistance is crucial for the products.

2.6. Chemical Resistance

It is a comparison of how well Nylon vs PLA resist exposure to different chemicals and doesn't degrade when exposed for extended periods. Nylon is resistant to oils, greases and some solvent making it a material of choice in industrial environments. And then the opposite of that, PLA is not very chemically resistant and can degrade when it comes in contact with a certain class of solvents. To be seen, Nylon yields superior performance in chemically profligate environments.

3. Applications of Nylon vs. PLA

Nylon is used for its popularity in textiles to create fabrics such as stockings, activewear, etc,.

| Nylon vs PLA |

Nylon |

PLA |

| Applications |

- Automotive Components: Nylon is widely utilized in the automotive sector for engine components such as gearbox, gears and fuel lines. Being strong, withstanding heat and relatively light in weight implies that it is excellent for lowering the weight of vehicles but retaining performance. For Instance, they are used in Nylon gears in powertrain systems for power assist which are very durable and operate smoothly under high temperatures.

- Textile and Apparel: Nylon is used for its popularity in textiles to create fabrics such as stockings, activewear and even parachutes. It is stretchy, has abrasion resistance and wicks away moisture making it perfect for high end performance fashion. Nylon protective clothes examples are very easy to see everywhere which is flexible and durable for people in many fields.

- Industrial Machinery: Nylon is also popularly used in industrial machinery (conveyor belts, bearings, rollers etc). In many applications, low friction, wear resistance, and heavy load handling are main factors that enhance the life and productivity of machinery. For example, Nylon rollers in assembly lines are smooth and easy running, with minimum maintenance like the case of Nylon gears.

- Electronic Parts: Nylon possesses high heat resistance and insulating highly suited to electrical/electronic applications such as cable ties, connectors, housing electrical appliances. The components hardened with Nylon are not conducting hence non corrosion. In fact, this can be Nylon cable ties in many electric supply systems or reinforcement.

- Outdoor Equipment: Nylon is considered as a key to outdoor equipment. Many applications such as table, chair, playground, tents, ropes also can be made from nylon. The perfect outdoor performance is strength, lightweight and weather resistant. This is precisely why Nylon ropes are the go-to strength and dependability of premium climbing gear or outdoor application.

|

- 3D Printing Products: PLA is one of the most common materials to be used for 3D printing; though it is difficult to work with, and has a high melting temperature. Due to its biodegradability and ability to obtain fine prints, it is great for prototyping as well as samples in education. PLA, for example is commonly used as the stuff that models, toys, body parts, maps and custom parts are printed in by professionals both to create 3D prints.

- Packaging: PLA is commonly used to create biodegradable packaging items like bottles, food wraps, food containers, packaging of creams, shampoos or lotions, etc. It has the same properties as normal plastic, but it is compostable. Its sustainable properties are the ability to increasingly lower plastic waste and also provide a range of safe products packaging for human health. Plastics covers made from PLA are becoming more common among beauty brands and the food and beverage industry with desires to make an eco-friendly impression on customers.

- Medical Applications: PLA can be biocompatible and biodegraded, hence it is used in medicine. There are PLA surgical sutures, implant and drug delivery systems. It is digestible by the body, so no additional procedures are necessary. One of the most popular applications is that PLA sutures can be dissolved overtime so there is less need for clinical care.

- Disposable Products: PLA is alway available for disposable items like utensils, cups, bottles, plates and straws. PLA is also great for these products because of how great it is at breaking down, making it an environmentally friendly alternative to single use plastics. An example of this would be the revolutionary straws that are starting to be commonly found in eco-conscious restaurants just replacing their previous use of plastic.

|

4. Which Plastic Should You Choose?

From these two extremely useful plastics, Nylon vs PLA have different properties and cater to different needs. Both materials play essential roles in current manufacturing, offering solutions developed for the satisfaction of diversified demands. However, there are two crucial factors that determine choosing between Nylon vs PLA:

Nylon vs PLA have different properties and cater to different needs

- The operating environment: In particular, Nylon performs outstandingly in environments characterized by high stress and temperature, such as automotive parts or industrial machinery, where strength and thermal stability are important. PLA, however, is better tailored for applications that involve an ecological system that includes composting packaging or disposable food service products. Consideration of the use environment will help ensure the properties of the material are in concert with operating conditions.

- Functional needs: Comparing the demands for strength, flexibility, stiffness or other specific needs of the application provides a well-rounded, efficient means of selecting between Nylon vs PLA. Nylon has emerged as the right material for long-term, high-performance applications involving gears, conveyor belts, and textiles due to its toughness, abrasion resistance, and flexibility. On the other hand, PLA comes out on top in those products where biodegradability and renewability are required, such as in medical sutures, 3D printed prototypes, or ecologically friendly cutlery.

5. Conclusion

In conclusion, both Nylon vs PLA are vital materials, each at the core of different modern industries. Whereas resistance to wear and tear, strength, and durability make Nylon irreplaceable in heavy-duty and high-performance uses, the biodegradable nature and renewable sources of PLA provide a ready market that is increasingly seeking sustainable solutions. Both types of plastics have market demand related to their respective advantages.

In the future, Nylon will properly remain right at the forefront in developments in industrial and technical areas needing strength and durability. The PLA will be actively involved in contributing to sustainability in a more eco-friendly world as industries move to adopt green policies that minimize environmental harm.

6. About EuroPlas’ PA Products and Bioplastics

EuroPlas is proud to be the world's leading supplier of high-quality plastic materials. EuroPlas products are a range of advanced material solutions designed for applications that require durable performance and excellent sustainability. Our team of experts is constantly researching and developing in creating custom material formulations that ensure optimal performance for each project. In particular, we are honored to bring PA and Bioplastics product lines with accompanying additives to perfectly meet diverse industrial needs.

EuroPlas honored to bring PA and Bioplastics product lines with accompanying additives

With many years of experience, EuroPlas guarantees a comprehensive supply of high-grade PA compounds. This product helps manufacturers create products that are precise, durable and reliable. PA compound of EuroPlas is a combination of a series of properties such as easy processing, cost-effectiveness, heat resistance, hardness and excellent abrasion resistance. Here are two typical PA product lines that will make a difference for your project:

Not stopping there, EuroPlas is also constantly striving on the journey to develop high-quality Bioplastics. Exclusively developed by EuroPlas, BiONext is a biodegradable biocomposite with superior mechanical properties. The product is made from renewable materials such as polylactic acid (PLA) and polyhydroxyalkanoate (Phase), plants (corn, palm oil, potatoes). The finished products made from biont biocomposite can be easily decomposed within 12 months. After decomposition, BiONext biomass can continue to be used as agricultural fertilizer, thus creating a circular life cycle for the product. This is the premise for sustainable development because of the foundation of the ecosystem and is environmentally friendly. Some of Bionext's representative products are:

Europlas ensures that our product's processes are always strictly controlled to meet all high standard requirements. Contact EuroPlas today to get the best advice for your upcoming project!