In today's rapidly evolving world, the integration of advanced technologies has revolutionized various industries, including material science. There is an innovative solution that attracts more attention: antibacterial additives. These compounds, often incorporated into a wide array of materials, play a pivotal role in safeguarding against the proliferation of harmful microorganisms. But what exactly are antimicrobial additives, and how do they function? Let's delve into the realm of antimicrobial additives to uncover their significance and applications in modern materials.

Read more: What are plastic additives? 8 most common plastic additives in plastic industry

1. The definition of antimicrobial additives

What are antimicrobial additives?

These additives are designed to target a wide range of microbes, including bacteria, mold, fungi, algae, and viruses, thereby ensuring the production of cleaner, more resilient, and longer-lasting products. Antimicrobial additives play a crucial role in enhancing the hygiene and durability of various materials by inhibiting the growth and spread of harmful microorganisms.

Utilizing antimicrobial additives offers several benefits:

- Decreasing the presence of bacteria that cause illness and infection

- Halting the proliferation of mold and mildew, which can be unpleasant

- Minimizing the growth of bacteria responsible for stains and odors

- Preventing physical deterioration caused by bacteria and fungi, which can degrade plastics and their additives

Antimicrobial additives can be categorized into two main types: organic and inorganic.

- Organic antimicrobial additives are composed of relatively small molecules that interact with microorganisms, preventing their reproduction. Some organic antibacterial additives are Triclosan, quaternary ammonium compounds (QACs), and certain plant extracts.

- Inorganic antimicrobial additives, on the other hand, are typically incorporated into plastic products during manufacturing. They are gradually released to the surface, providing long-lasting protection against microbial growth. Examples of inorganic additives include silver, copper, and zinc.

Incorporating antimicrobial additives into materials and products not only enhances their hygienic properties but also promotes public health by reducing the risk of microbial contamination and transmission. By leveraging the advancements in antimicrobial technology, industries can continue to produce innovative and safer solutions for diverse applications.

Read more: How biodegradable plastics break down?

2. Differences between antimicrobial additives and antimicrobial plastic

Antimicrobial additives and antimicrobial plastics are both used to inhibit the growth of microorganisms such as bacteria, fungi, and algae. However, they differ in their application and integration into materials. Here are the key differences between the two:

2.1. Nature of integration

- Antimicrobial additives: These are substances added to a base material during manufacturing or processing to impart antimicrobial properties. They can be mixed into various materials like plastics, paints, textiles, etc.

- Antimicrobial plastics: These are plastics that have antimicrobial properties inherently integrated into their molecular structure. This means that the antimicrobial properties are a fundamental part of the material itself and not added as an extra component.

2.2. Performance

- Antimicrobial additives: The effectiveness of antimicrobial additives can vary depending on factors such as concentration, distribution within the material, and compatibility with the base material. They may require regular replenishment or reapplication over time.

- Antimicrobial plastics: Antimicrobial plastics offer consistent and long-lasting antimicrobial properties throughout the material's lifespan. Since the antimicrobial agents are embedded within the material, they are less prone to degradation or leaching, providing more durable protection.

2.3. Flexibility

- Antimicrobial additives: Additives offer flexibility in terms of application, as they can be incorporated into various materials during manufacturing or even added to existing products.

- Antimicrobial plastics: This is a permanent form of material that cannot be integrated into other materials, providing a more permanent and integrated solution.

3. Applications of antimicrobial additives

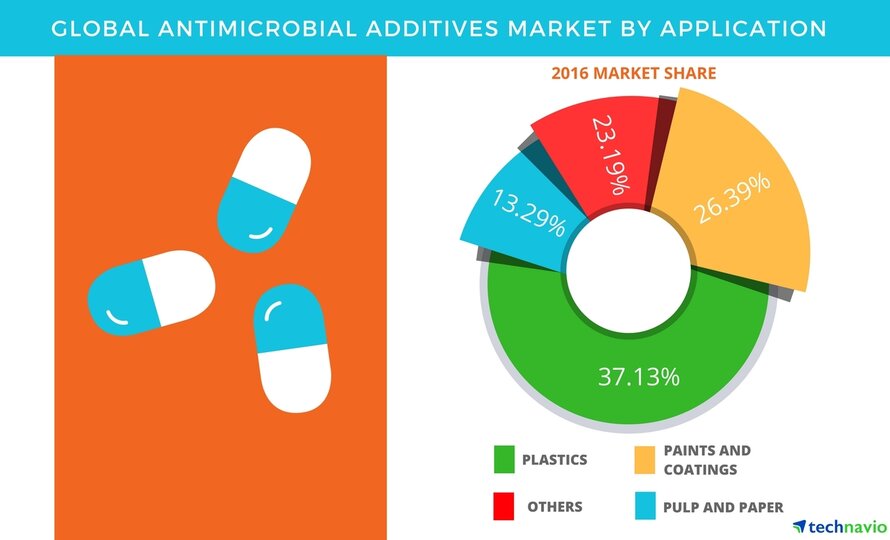

Some data on the demand for antimicrobial additives

Antimicrobial additives offer versatile solutions across various industries, providing sustainable and effective preservation properties. Here are some common applications where antimicrobial additives play a crucial role:

3.1. Plastics industry

In the plastic manufacturing industry, the degradation and discoloration of polymers pose significant challenges. Microorganisms such as yeasts, mold fungi, bacteria, and algae contribute to polymer degradation over time.

Antimicrobial additives are incorporated into polymer compounds during molding or compounding processes to combat microbial growth. By providing a biocidal effect, these additives help protect plastics, extending their lifespan and maintaining their aesthetic appeal.

Read more: Antimicrobial plastic: What you need to know

3.2. Paints and coatings sector

Antimicrobial additives are commonly used in paints and coatings to preserve surface integrity and prevent microbial proliferation. Industries ranging from real estate to automotive utilize antimicrobial coatings to ensure product longevity and hygiene.

In developed regions like North America, Western Europe, and APAC, the adoption of innovative coatings with antimicrobial properties is on the rise, driven by the increasing awareness of the health benefits associated with antimicrobial additives.

This trend underscores the importance of antimicrobial coatings in various applications, including automotive, shipbuilding, furniture, and consumer durables.

3.3. Pulp and paper manufacturing

The pulp and paper industry faces challenges related to microbial contamination, particularly in applications where hygiene is critical, such as packaging materials.

Antimicrobial additives are employed to mitigate microbial growth and maintain cleanliness in pulp and paper products. With the rising demand for packaged food products and the increased awareness of hygiene standards, the utilization of antimicrobial paper in packaging applications is expected to surge.

Additionally, the need to address cross-contamination risks associated with paper currency underscores the importance of antimicrobial additives in maintaining public health.

3.4. Antiviral protection

Antimicrobial additives, particularly those based on silver compounds, offer effective defense against viruses like H1N1 and Avian Influenza. They provide essential protection in environments where viral transmission is a concern.

3.5. Food packaging

Antimicrobial additives in food packaging

Antimicrobial additives are utilized in food packaging to inhibit the growth of microbes and extend the shelf life of food products. Silver ion technology, for example, can be incorporated into packaging materials to maintain food freshness and safety.

Active antimicrobial food packaging integrates silver ion technology into materials like PE, PET, PP, and biodegradable PLAs. These films extend shelf life by inhibiting microbial growth, ensuring fresher products for consumers.

Overall, antimicrobial additives offer multifaceted benefits across various sectors, contributing to enhanced hygiene, extended product lifespan, and reduced transmission of harmful pathogens.

4. EuroPlas - where you can find the additives you need

Plastic additives at EuroPlas

EuroPlas offers a comprehensive range of plastic additives designed to enhance the performance, durability, and aesthetic appeal of plastic products. Our additives are meticulously formulated to meet the diverse needs of manufacturers across various industries, ensuring superior quality and reliability.

Plastic additives play a crucial role in the production process, imparting specific properties to the finished products. At EuroPlas, we understand the importance of choosing the right additives to achieve the desired mechanical, aesthetic, and functional characteristics. That's why we provide a wide selection of additives tailored to meet the unique requirements of each application.

Our range of plastic additives includes:

- Clarifying additive: Clarifying additives enhance plastic transparency and mechanical properties. They're widely used in injection molding for items like housewares, food storage containers, caps, and closures, as well as in blown film and extruded sheets. Compatible with various resins including PP, HDPE, HDPE/PP, and LLDPE/PP.

- Optical brightener additive: Optical brightener additives enhance light reflectivity, meeting aesthetic requirements for end-products.

- Odor-removing additive: Odor-removing additives effectively eliminate unpleasant odors in recycled plastics, improving product quality and competitiveness. Widely used in rubber and plastic products, as well as items made from regrind materials like home appliances, toys, and textile packaging.

- Desiccant: Desiccant additives absorb moisture in plastic materials, reducing processing errors like bubbles and fisheyes, and enhancing end-product quality.

- Flame retardant: EuroPlas flame retardants are meticulously formulated to reduce the ease of ignition, minimize smoke generation, and slow down the rate of burn in plastic materials. Our flame retardants not only provide these crucial safety features but also offer high-impact properties, excellent thermal and dimensional stability, and superior scratch resistance, ensuring top-quality performance in various applications.

- Anti-fog additive: Anti-fog additives lower plastic surface tension, preventing water condensation. They enhance finished product quality without compromising mechanical properties or color.

- Anti-aging additive: With 14 years of expertise in the plastics industry, EuroPlas is committed to providing top-quality anti-aging additives. Our anti-aging additive is a trusted solution for plastic manufacturers, effectively halting the oxidation process that can degrade polymer mechanical characteristics. This ensures the plastic remains in optimal condition, extending its lifespan and maintaining its integrity over time.

- Processing-aid additive: Processing-aid additives from EuroPlas enhance the extrusion efficiency of thermoplastic resins, leading to smoother processing and improved aesthetics. By minimizing flow traces and die lines, these additives create glossy, transparent products with enhanced visual appeal.

- Anti-static additive: EuroPlas offers diverse anti-static solutions tailored to meet customers' surface resistivity and antistatic effect specifications. Our anti-static additives effectively dissipate or promote the decay of static electricity, enhancing processability, lubrication, and mold release in plastic manufacturing.

- Anti-UV additive: Anti-UV additives safeguard plastic materials against UV radiation by either absorbing or scattering UV rays, thereby thwarting potential damage. They can be incorporated into plastics during production or applied as a protective coating on the material's surface.

- Anti-blocking additive: The anti-blocking additive is employed to minimize friction between adjacent film layers during the blown film process, thereby enhancing the quality and effectiveness of the end products.

EuroPlas is committed to providing high-quality plastic additives that meet stringent industry standards. Our team of experts works closely with customers to understand their specific needs and recommend the most suitable additives for their applications. Thanks to EuroPlas plastic additives, you can achieve superior performance, durability, and aesthetics in your plastic products.

Choose EuroPlas to provide you with reliable plastic additives that deliver outstanding results. Contact us today to learn more about our product offerings and how we can assist you in achieving your manufacturing goals.