Plastics for machining have become favorable options in many industries. Choosing the proper type of plastic can thus have an effect on the end-piece performance and a rather major influence on its overall lifespan. In this guide, we will learn the considerations to make when selecting plastics for machining and learn about some of the best options out there.

1. Criteria for Selecting Plastics for Machining

1.1. Mechanical properties

In the selection of plastics for machining, the most vital properties that play a role are their mechanical properties. Attributes such as tensile strength, impact resistance, and stiffness describe material response to stressors.

Applications involving pulling forces need high tensile strength, but impact resistance ensures safety in an environment prone to shocks. Stiffness ensures plastic will keep its shape when the load is applied without deforming. It is from this that performance evaluation is done to ascertain whether the plastic selected can meet the performance requirements.

The most important consideration when choosing plastics for machining are their mechanical qualities.

1.2. Thermal stability

Thermal stability is very crucial in plastics for machining that are exposed to temperature fluctuations. Preeminently, materials need to maintain their integrity and performance during exposure to heat. High resistance to heat prevents warping; likewise, understanding thermal expansion is important in maintaining accuracy in dimensionality. Consideration of thermal stability allows for assured performance over conditions of operation.

1.3. Chemical resistance

Chemical resistance is essential to plastics used in media that contain aggressive substances. Different types of plastics for machining have different compatibility with chemicals and might influence durability. Materials can degrade on exposure to the type of solvents, leading to failure. Chemical resistance testing verifies the material properties retained with the plastic material over time for serving in industries like pharmaceutical and automotive industries.

1.4. Machinability

Machinability will be related to manufacturing efficiency: those plastics that can easily be cut, drilled, and shaped can save time and reduce costs. Generally, good machinability means a fine surface finish, which improves quality. By selecting plastics for machining with favorable machinability, manufacturers can achieve precision with optimization in the production process.

The machinability of plastics will be correlated with their manufacturing efficiency.

1.5. Cost-effectiveness

The material's performance and cost must be considered in terms of cost-effectiveness. High-performance plastics for machining are expensive at the beginning but stronger in the long run, thus saving costs. Thus, a vital computation of an overall cost of ownership is necessary to make an appropriate match with the budget objective accurately.

1.6. Availability

The material availability is important to prevent delays in production. The selected plastic for machining should be easily available, and specific grades or formulations might be required for special applications. Dependability of material supply is another factor toward better productivity and reduction of chances of disturbances in the manufacturing process.

1.7. Environmental impact

New material development should increasingly take into consideration environmental impact. It is critical to review the production process and life cycle of a material, with adherence to any related regulations. By selecting plastics for machining friendly to the environment, a manufacturer may help create sustainability that also will encompass the consumer's interest in environmental concerns.

Choosing environmentally friendly plastics for machining could contribute to sustainability.

2. Top Plastics for Machining

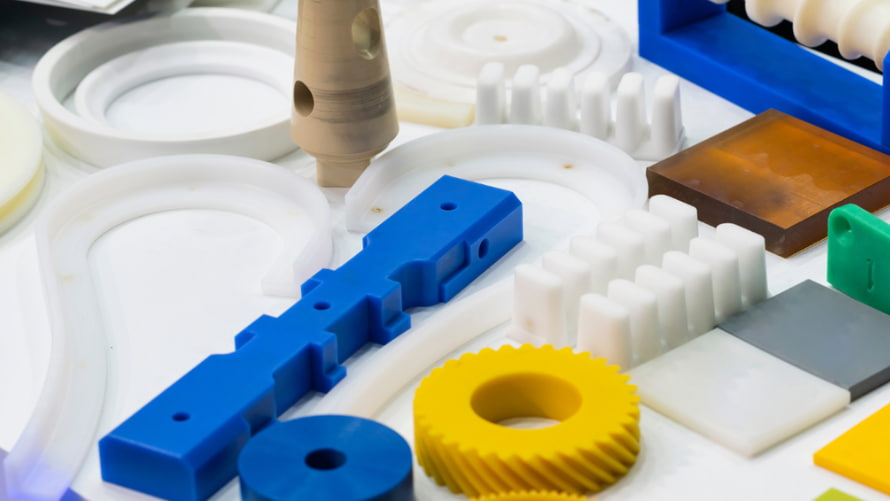

There are a number of plastics that work well in machining because of the properties and performance characteristics that make them unique. Here are some of the best machining plastics:

2.1. Acrylonitrile Butadiene Styrene (ABS)

Acrylonitrile Butadiene Styrene (ABS) is one of the most used plastics for machining because it is strong, rigid and can be used for impact applications. Easy to machine with standard cutting tools, it can be recommended for the kind of cuts and finishes usually achieved when manufacturing products.

2.2. Polycarbonate (PC)

Polycarbonate is one of the most popular engineering plastics for machining, known for its highest impact strength and very good thermal stability. Some of the tough plastic will not easily break even with heavy force; therefore, it has been employed in several functions in some forms of protective eyewear like safeties, some shields, and some automobile parts. Such transparencies and non-fading to yellow color, when exposed to UV, make it more useful.

2.3. Nylon (PA)

With a whole profile of wear resistance and low friction, nylon is a common choice of plastics for machining for gears and bearings. This is due to its enhanced performance features, which include good strength and different grades of moisture resistance.

Nylon is one of the plastics for machining.

2.4. Polyoxymethylene (POM)

As a plastic for machining, POM boasts a number of very useful properties: it is very rigid yet possesses extremely low friction. Because of its rigidity, stability of dimensions, and toughness, POM sees extensive use in precision parts for both automotive and industrial applications.

2.5. Polyethylene (PE)

The versatility of polyethylene and its relative cheapness translate to one of the most extensively used plastics for machining. Since it is light, resistant to chemicals, and easily machinable, it is put into a number of uses ranging from containers to piping systems and insulation. Variations in grade, such as HDPE and LDPE, allow for a range of strengths and flexibilities suitable for different uses.

2.6. Polypropylene (PP)

Regarding plastics for machining, polypropylene material is chemically inert, flexible and has the least density among other material types. Automobile and medical packaging parts appear to be some of the key areas where the material can be applied. This is an effective quality of the material since it does not break when pressure is applied severally in products that need reliability and resilience.

Polypropylene (PP) is another plastic for machining.

3. Conclusion

The choice of plastic for machining remains an important factor in all applications. Consideration of essential factors such as mechanical properties, thermal stability and cost is required to make a more informed choice of material based on requirements.

4. About EuroPlas

EuroPlas is one of the premier suppliers of high-quality plastics for machining. As a company with a future-oriented approach to innovation and quality service delivery, we showcase a portfolio of preferred plastics suitable for various industries.

Our product portfolio includes:

1. ABS:

2. PP:

3. PE:

4. PA:

5. PC:

For more information, contact us today!