Reinforcement materials used in plastics are important in improving the performance characteristics of strength, stiffness, and durability. Because of the balance between strength and cost-effectiveness, reinforcement materials play a very important role in modern engineering and manufacturing. Understanding the properties and advantages of reinforcement materials is one of the most basic steps to dramatically improve project performance. The following article will open up more detailed perspectives on the wonderful aspects of reinforcement materials. Find out below!

1. Why Is Reinforced Plastic Important?

Reinforcement materials are the combination of reinforcing materials and plastic to create a more advanced material line

Reinforcement materials play an important role in the modern materials industry because of their many outstanding advantages. Reinforcement materials are the combination of reinforcing materials such as glass fibers or carbon fibers to create a more advanced material line. This process brings higher performance to plastic materials such as higher strength, stiffness, and impact resistance while maintaining a lightweight structure.

Reinforcement materials are essential in many manufacturing industries in human life today. They are considered one of the most important materials used in aerospace, automotive, and construction manufacturing processes, etc. They help devices and applications in life possess a high strength-to-weight ratio, good corrosion resistance, good mechanical load distribution, and protect the plastic matrix from damage. Because of the above advantages, the life of the device is extended, reducing the need for maintenance, thereby bringing great benefits with cost efficiency.

2. A List of Reinforcement Materials for Plastic

There are many types of reinforcement materials for plastic materials, each with its own unique characteristics that benefit different applications. Here are some common types:

2.1. Glass Fibers

Glass fibers will be mixed into the plastic matrix to improve the properties

This is one of the most popular reinforcement materials today. In it, thin glass fibers are used to reinforce plastic. They will be mixed into the plastic matrix to improve the properties of the material to become more advanced.

This type of reinforcement materials is widely used in automotive parts, boat hulls, and construction materials. They help applications demonstrate strong tensile strength, stiffness, heat resistance and good corrosion resistance at a reasonable cost.

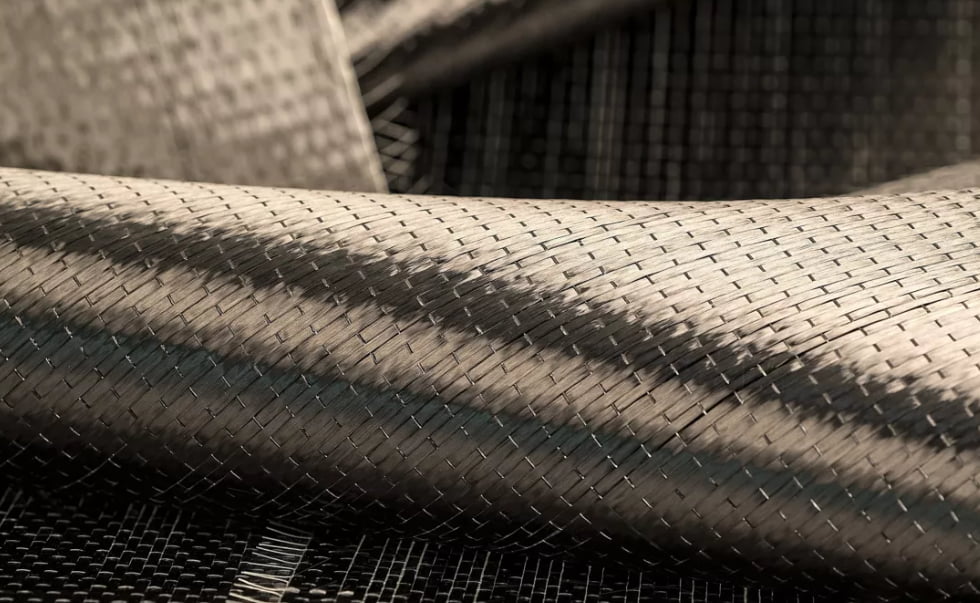

2.2. Carbon Fibers

Carbon fiber is through the method of embedding and layering them into plastic matrix

Another equally popular type of reinforcement material is carbon fiber. Carbon fiber is a thin, extremely strong fiber created by arranging carbon atoms in a crystalline structure. The production process of this type of reinforcement material is through the method of embedding and layering them into an epoxy or thermosetting resin matrix.

Carbon fibers are used in the aerospace industry, protective parts, sports equipment and high performance engine components due to their light strength. The application will have an excellent strength-to-weight ratio, along with the commendable stiffness and heat resistance of carbon fibers. However, they are much more expensive than the reinforcements used elsewhere.

Read more: Differences between fiberglass and carbon fiber

2.3. Aramid fibers

Aramid fibers are incorporated into resins to create a line of impressive reinforcement materials

Aramid fibers are a family of synthetic fibers with high strength and heat resistance. They are drawn into fibers and incorporated into resins to create a line of reinforcement materials that are impressive in terms of performance and quality.

Their high impact resistance makes them suitable for use in protective equipment, bulletproof vests and many other highly stressed industrial components. They offer many benefits to the application such as being lightweight, extremely strong, having excellent abrasion resistance and high temperature resistance.

Read more: What is Aramid fiber?

Read more: Aramid Fiber vs Carbon Fiber: What are the differences?

2.4. Natural fibers

These reinforcement materials are reinforced in an environmentally friendly way

Reinforcement materials are also contributed by natural fibers. These fibers include jute, flax, and hemp, and some are derived from plants. They are favored because these reinforcement materials are reinforced in an environmentally friendly way. During the manufacturing process, these fibers are processed and combined into a plastic compound. This process usually involves extrusion or molding.

Some common applications of these reinforcement materials include automotive interior panels, furniture, packaging materials, etc. The use of natural fibers is considered a sustainable alternative due to their biodegradability and environmental friendliness. In addition, they are lightweight, quite durable, and are considered an ecological choice in the manufacturing industry.

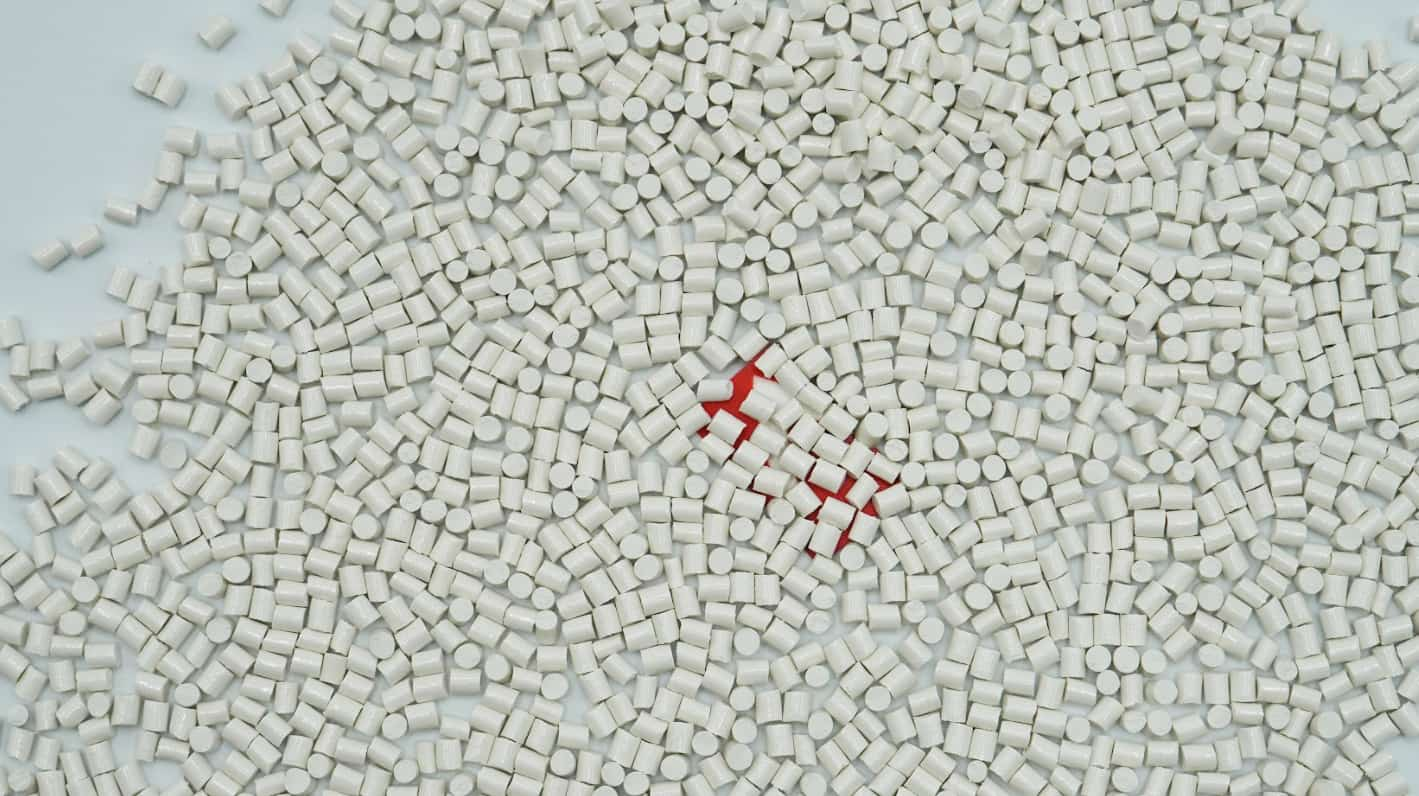

2.5. Mineral Fillers

The benefits of mineral fillers include increased stiffness, improved heat resistance

They can be derived from reinforcing agents such as Calcium carbonate, talc and mica. These mineral fillers effectively enhance the properties of plastics. These minerals are ground into fine powder and dispersed during processing into the plastic matrix.

The applications of these reinforcement materials have been found in the automotive, construction and packaging industries, etc. due to their ability to reduce costs and achieve dimensional stability in products. The benefits of mineral fillers include increased stiffness, improved heat resistance and significantly reduced shrinkage of plastic materials.

3. How Reinforcement Materials Improve Plastic Performance

Reinforcement materials tend to increase performance in plastics through improved mechanical and structural properties. Here are the details concerning reinforcement materials that improve plastics' performance:

3.1. Improved strength and rigidity

The addition of glass, carbon, and aramid fibers as reinforcement materials confers plastics with much better tensile strength and stiffness than unreinforced plastics. They distribute the mechanical loads, hence forbidding deforming or failure of the material under stress. They even provide feasibility to plastics in high-stress applications like automotive parts and structural components.

3.2. Improved impact resistance

The impact energies are absorbed and distributed more reasonably by reinforced plastics more than any other material, particularly those reinforced with aramid and carbon fibers. The higher resistance translates to toughness, which is a function of the capability of a material to absorb energy without fracturing. This makes this material so important in protective gear, sporting, vehicle panels amongst others.

Reinforcement materials have better dimensional stability compared to unreinforced plastics

3.3. Thermal stability

The reinforcement materials, particularly carbon and mineral fillers, enhance the heat resistance of plastics, improving their stability at high temperatures. Because of such thermal improvement, applications are being extended to aerospace, electronics, and automotive engines where exposure to extreme heat is very high.

3.4. Lightweight structure with high strength-to-weight ratio

Reinforced material gives strength to lightweight plastic material. This feature is very important in industries dealing with aerospace and automotive since the reduction in weight boosts fuel efficiency. Manufacturers do not need to give up performance for strength.

3.5. Improved dimensionality and higher wear resistance

Because of the addition of fillers in the material composition, these plastic materials have better dimensional stability compared to unreinforced plastics. This material neither shrinks nor warps over time. In addition, it will neither shrink or expand due to temperature changes and moisture. The reinforced material that encourages resistance to wear to protect components against friction in gears, bearings, and conveyor belts.

4. Conclusion

In conclusion, reinforcement materials are considered as one of the advanced materials that play an important role in many manufacturing industries today. Reinforcement materials are the main components that help plastics become high-performance plastic materials thanks to their increased strength, stiffness and thermal stability. The most popular reinforcement lines include glass fibers, carbon fibers, aramid fibers, natural fibers and mineral fillers, etc. By incorporating reinforcement materials into the material, plastics can achieve the most demanding and advanced manufacturing requirements.

5. About EuroPlas’ Reinforced Plastics

EuroPlas is a leading plastics manufacturer in Vietnam with extensive experience. We specialize in the production of high quality glass fiber reinforced plastic compounds and related products.

EuroPlas uses modern equipment and quality control processes to ensure the consistency and reliability of our products

We are proud to be the leader in providing glass fiber reinforced plastic compounds that can be customized to meet customers' design requirements (e.g. color, strength and stiffness, etc.). EuroPlas' experienced team of engineers and technicians work closely with customers to understand their requirements and develop suitable solutions to meet their needs.

EuroPlas uses modern equipment and quality control processes to ensure the consistency and reliability of our products. We are committed to providing exceptional customer service and support, focusing on providing high quality products at competitive prices.

In addition to fiberglass compounds, EuroPlas offers a wide range of other compounds and resins, including Bioplastic compounds, Plastic additives and Bioplastic compounds. These products can be used to enhance the performance of materials in a variety of applications. Contact EuroPlas today for a sustainable material solution!