Engineering plastic compound is a common material in producing parts and details of products in various industries. Due to its popularity and ease of use, many product manufacturers in different fields are looking for plastic compounders, especially engineering plastic compounders in India.Our article will provide a suggested list of companies. But before that, let's get to know more about the material in the section below! Follow up!

1. Overview of Engineering Plastic Compound

1.1. What is it?

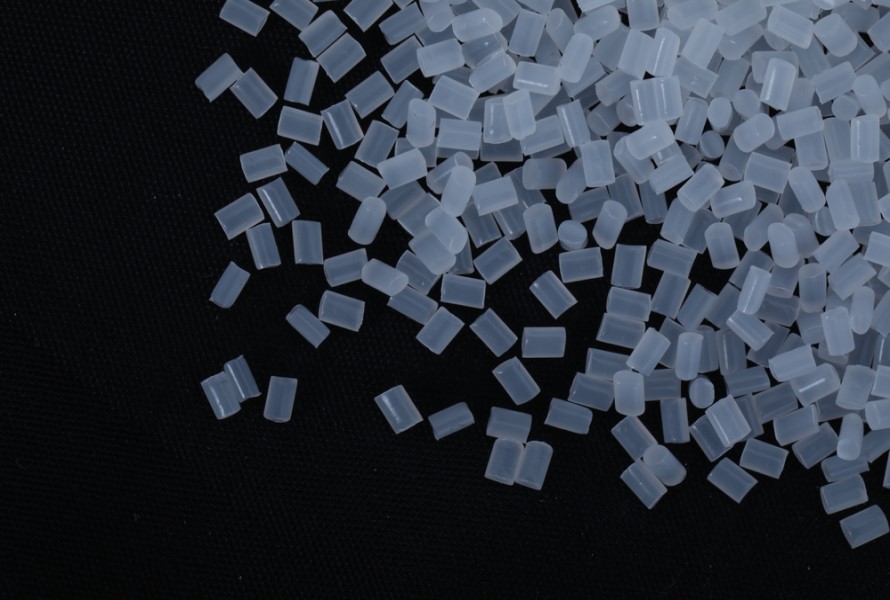

Engineering plastic compound or

polymer compound is the combination of primary plastic, coloring agents, and reinforcing agents to improve specific properties suitable for the end products' requirements.

Common additives and reinforcements included in the mixture are Glass beads/fibers, Ceramic beads, Barium Sulfate Powder (BaSO4), Talc mineral with high purity, Clay with nanoscale, Conductive carbon black, and Flame retardant with or without halogen.

1.2. Outstanding Features

Most engineering plastic compounds are designed to meet the following standards:

- Good dimensional stability

- Great stiffness

- Conductive

- Low coefficient of thermal expansion

- Increased heat strain temperature

- High impact resistance

- Low moisture absorption

- Better scratch resistance

- Flame retardant standards: UL94 V0, V1, V2

Here is more information about what compounding in polymer is and the common types of polymer compounding.

1.3. Why Engineering Plastic Compound?

It's tailored-made for each finished product to improve the product's quality. The material is customizable to fit each requirement of an enhanced feature.Full features are in a single material, making it more convenient for manufacturers to use in making their final products. It's a cost-saving method to improve productivity.

2. Engineering Plastic Compounders in India

2.1 Appl Industries Limited

It's a private limited company founded in 1990. It took more than 20 years for Appl to grow as one of the biggest compounders of engineered thermoplastics in India. Its location is in Hinjewadi, Pune, Maharashtra. It has the capacity to produce 100,000 MTPA. Its main products include Polypropylene Compound and some other compounds.

2.2. Mitsubishi Chemical India Pvt. Ltd.

Mitsubishi Chemical India is a subsidiary company of Mitsubishi Chemical Corporation, which belongs to the Mitsubishi Chemical Holdings Corporation, whose headquarters is in Tokyo, Japan. Since 2008, the company has been assigned with selected activities of its parent company and cooperates with other group companies such as Mitsubishi Chemical 2.3. Medience Corporation.

Its products mainly focus on Polypropylene Compounds, Carbon Fiber, Ion Exchange Resin, Synthetic Papers, Cosmetic Raw Materials, and Lithium Ion Battery.

2.4. Prabhu Poly Color Private Limited

The company was established in 2005 and is the leading manufacturer of engineering plastic compounders in India. Its location is in Kolkata, West Bengal.

Prabhu Poly Color Private Limited supplies a wide range of products such as Polymer Compounds, Color Masterbatches, Additive Masterbatches, Cable Compounds, White Masterbatches, Calcium Filler Masterbatches, Metallic Masterbatches, etc.

2.5. Inno Color And Compounds Private Limited Company

Inno Color & Compounds Private Limited was founded in 2001. The company has quite a long history of development before becoming one of the leaders in the masterbatch field in India. They are a manufacturer and also an exporter.

The company's range of products and services include Polymer Compounds, Thermoplastic Compound, Polypropylene Compound, White Masterbatches, Black Masterbatches, etc.

2.6. Peeco Polytech Pvt Ltd Business

This Peeco Polytech Pvt Ltd Business was founded in 2008 at Narela Industrial Area, Delhi. It's a reputed firm in the domestic and international markets.

The company has a wide range of productions, including:

- PP Compounds: Talc/Mineral/Calcium-filled Filled Compounds and Glass Filled Polypropylene Compounds

- ABS & SAN Compounds: Pre Coloured, Glass Filled & Flame Retardant

- Thermoplastic Elastomer Compounds

- PPCP, PPHP, LLDPE, and ABS granules for compounding and injection molding applications.

2.7. Aquent Polymers Private Limited Business

The company started its business in 2016 and is one of the developing engineering plastic compounders in India. Its office is located in New Delhi.

Some of their highlighted products include engineering plastic compounders in India, Nylon Granule, ABS Plastic Granules, HIPS Granules, and Nylon 66 Granule.

3. EuroPlas - A Worth-Considering Engineering Plastic Compounder From Vietnam

As a leader in the masterbatch industry, EuroPlas offers a wide range of optimal solutions with flexibility, high quality, and all functions in just one material for your business. It allows you to process directly without any material added. The material also can be tailor-made based on the final products' requirements. Our engineering plastic can be used in automobile, electronics manufacturing, interior decoration, and renewable energy,

EuroPlas products include PBT GF-FR compound, PA6, PA66 blend compound, PC flame retardant compound, ABS Glass fiber compound, ABS antistatic compound, etc., guaranteeing you high-quality end-products. Let's have a look at our list of

Engineering Plastic Compounds below!

It's an engineering plastic comprising PBT plastic with glass fiber reinforcements, color, and flame retardant additives. Our material also obtains glass fiber ratios and fire resistance levels that meet the UL94 standards, including 5VA, 5VB, V0, V1, and V2. Therefore, EuroPlas is confident to be your reliable supplier for PBT GF-FR Compound and other products.

PP engineering plastic compound is a blend of PP resin and special reinforcing agents such as flame retardant additives, conductive black carbon, talc mineral, fiber/glass beads, etc. Depending on the requirements of the final product's characteristics, manufacturers will choose what reinforcements to combine.

We have:

3.3. HIPS

It's the blend of HIPS resin and other additives such as flame retardant carbon black conductive. It's known to improve the performance of final products. Their application includes Mobile chargers, Power sockets, Electronic Components, earphones, Electronic component pallets, Consumer goods, Packaging and Toys. We have:

It's the blend of HIPS resin and other additives such as flame retardant carbon black conductive. It's known to improve the performance of final products. Their application includes Mobile chargers, Power sockets, Electronic Components, earphones, Electronic component pallets, Consumer goods, Packaging and Toys. We have:

3.4. PA (Nylon) engineering plastic compound

Polyamide-6 (PA6) and Polyamide-66 (PA66) are among the top choices for manufacturing thanks to their outstanding properties. The former is cheaper, easier to process, and distorts less, while the latter is stiffer and has higher temperature resistance and better abrasion resistance. EuroPlas has added other additives to the PA6 and PA66 resin to increase their performance.

Polyamide-6 (PA6) and Polyamide-66 (PA66) are among the top choices for manufacturing thanks to their outstanding properties. The former is cheaper, easier to process, and distorts less, while the latter is stiffer and has higher temperature resistance and better abrasion resistance. EuroPlas has added other additives to the PA6 and PA66 resin to increase their performance.

- PA6, PA66 blend compound: PA6, PA66 Blend compound combines PA6/PA66 resin, elastomer, and impact strength modifiers, giving it resiliency and strong mechanical properties. This material from EuroPlas will help you produce mechanically strong and highly precise final products. Its application includes roller bearings, carburetors, control valves, exhaust gas, and other gear-related components.

- PA66, PA6 Glass fiber compound: PA resin is mixed with glass fiber reinforced, providing the PA66 and PA6 Glass fiber compound with toughness, mechanical strength, high heat deflection temperature, chemical resistance, and wear resistance. With 30-50% of glass fiber, EuroPlas PA66, PA6 Glass fiber compound is ideal for producing drive belts, bearings, gears, carburetor components, household electrical components, and computer details.

3.5. Polycarbonate Engineering Plastic Compound

Polycarbonate engineering plastic compound is mixed between the polycarbonate base, reinforcing agents, and additives. Its purpose is to create a material meeting the property requirements of the final products. The end products can achieve special properties thanks to the compound. Engineering plastic is commonly seen in electronics and automobile manufacturing, interior design, and renewable energy.

Polycarbonate engineering plastic compound is mixed between the polycarbonate base, reinforcing agents, and additives. Its purpose is to create a material meeting the property requirements of the final products. The end products can achieve special properties thanks to the compound. Engineering plastic is commonly seen in electronics and automobile manufacturing, interior design, and renewable energy.

EuroPlas Polycarbonate engineering plastic compound includes:

- PC glass fiber compound: a mixture of polycarbonate resin and glass fiber with rigidity, heat, and impact resistance.

- PC flame retardant compound perfectly combines polycarbonate resin and halogen flame retardant. It's lightweight, transparent, durable, impact-resistant, and high-temperature resistant.

3.6. ABS Plastic Products

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic polymer known for its toughness, heat resistance, and impact resistance. ABS is commonly used in a wide range of applications, such as electronic housings, automotive parts, and toys, due to its mechanical properties and ease of processing.

ABS (Acrylonitrile Butadiene Styrene) is a thermoplastic polymer known for its toughness, heat resistance, and impact resistance. ABS is commonly used in a wide range of applications, such as electronic housings, automotive parts, and toys, due to its mechanical properties and ease of processing.

- ABS Antistatic compound: It's the combination of ABS resin and antistatic additive. It helps prevent surface static, thus minimizing the risk of electrostatic discharge and ensuring safety during processing and product use.

- ABS Glass Fiber Compound: It's a combination of ABS resin, glass fiber, and suitable additives. It can increase the stiffness, heat deflection temperature (HDT), and softening point (VICAT) of end-products.

- ABS flame retardant compound: It is made of ABS resin and flame retardant additives, which are in different fire resistance levels according to UL94 standards: V0, V1, and V2. It's well-known for its ability to prevent fire spread on plastic surfaces.